Dennis, or anyone knowledgeable, I came across an article on another SI thread that talked of a molten salt reactor that appears to be much safer and what is currently being used. Now, I am not a physicist, scientist nor engineer so I may be missing something but I cannot understand why this molten salt reactor is not the standard for producing atomic energy.

This is the start of the article and the rest of it at the url provided.

TIA for any help

Peter

en.wikipedia.org

Molten salt reactor

From Wikipedia, the free encyclopedia

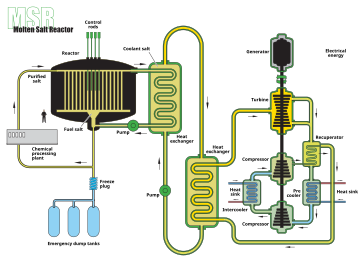

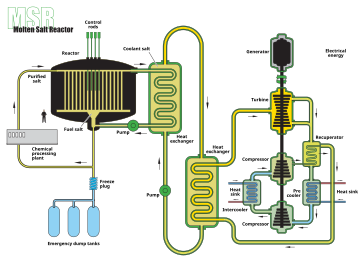

Molten salt reactor scheme.

A molten salt reactor (MSR) is a type of nuclear fission reactor in which the primary coolant is a molten salt mixture. MSRs run at higher temperatures than water cooled reactors for higher thermodynamic efficiency, while staying at low vapor pressure.

The ability to operate at near atmospheric pressures reduces the mechanical stress endured by the system, thus simplifying aspects of reactor design and improving safety. The nuclear fuel may be solid fuel rods or dissolved in the coolant itself.

One kind of a MSR is the liquid fluoride thorium reactor (LFTR), recently described by Kirk Sorensen at Mount Royal University. [1]

In many designs the nuclear fuel is dissolved in the molten fluoride salt coolant as uranium tetrafluoride (UF4). The fluid becomes critical in a graphite core which serves as the moderator. Fluid fuel reactors have significantly different safety issues compared to solid fuel designs; the potential for major reactor accidents is reduced, while the potential for processing accidents is increased. [2]

More recent research has focused on the practical advantages of the high-temperature low-pressure primary cooling loop. Many modern designs rely on ceramic fuel dispersed in a graphite matrix, with the molten salt providing low pressure, high temperature cooling. The salts are much more efficient at removing heat from the core, reducing the need for pumping, piping, and reducing the size of the core as these components are reduced in size.

The early Aircraft Reactor Experiment (1954) was primarily motivated by the small size that the design could provide, while the Molten-Salt Reactor Experiment (1965–1969) was a prototype for a thorium fuel cycle breeder reactor nuclear power plant. One of the Generation IV reactor designs is a molten salt-cooled, solid-fuel reactor; the initial reference design is 1000 MWe with a deployment target date of 2025.

Another advantage of a small core is that it has fewer materials to absorb neutrons. In a reactor employing thorium fuel, the improved neutron economy makes more neutrons available to breed thorium-232 into uranium-233. Thus, the compact core makes the molten salt design particularly suitable for the thorium fuel cycle. |