Recycling

Battery recycling: How advanced materials science is changing the game

The future of battery recycling is promising and continuous advancements in materials science are driving the development of more efficient, sustainable processes.

By

Manikumar Uppala

Dec 03, 2024

Industry

Recycling

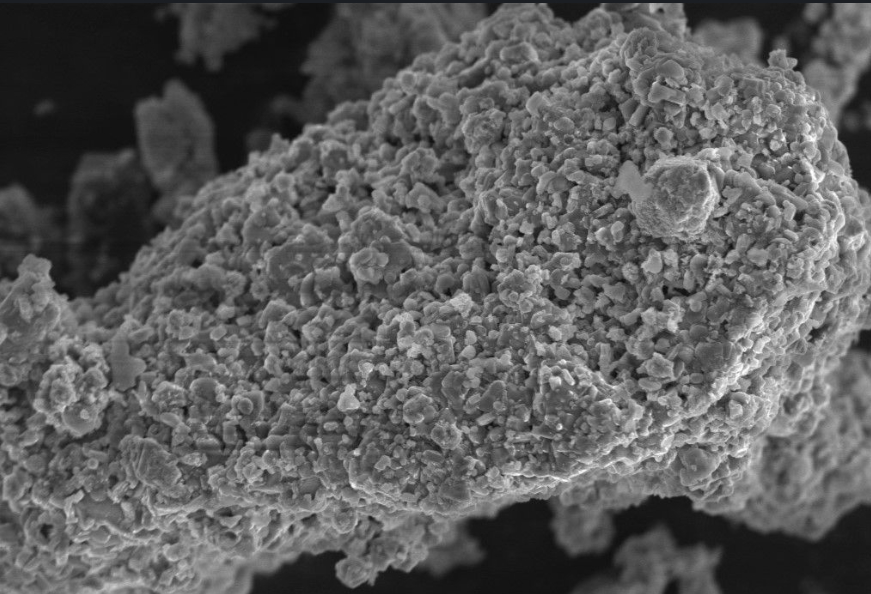

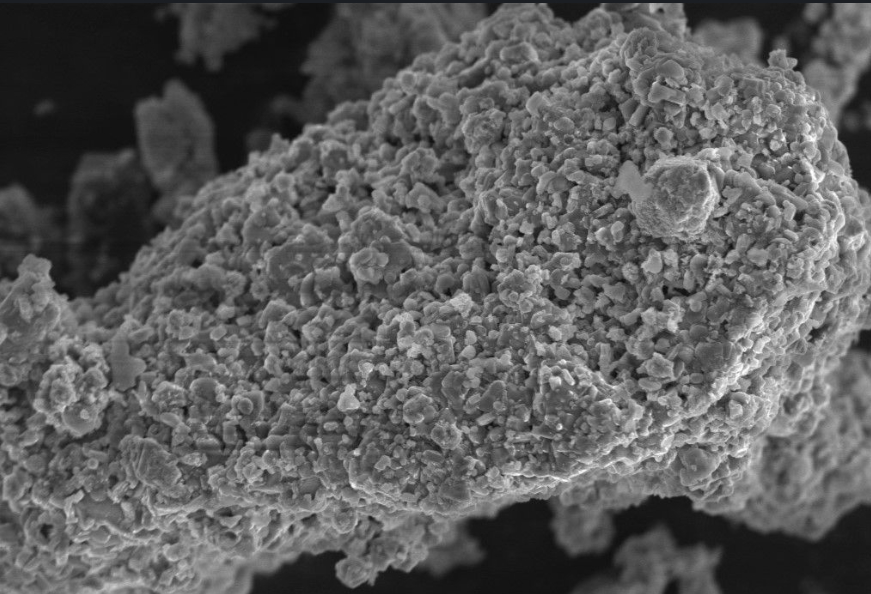

A scanning electron microscope image of a cobalt and nickel metal mixture powder extracted by Metastable Materials by recycling lithium ion batteries. | Image: Metastable Materials

The growth of electric vehicles and energy storage solutions has led to a rapid rise in the demand for batteries and, consequently, for efficient and sustainable battery recycling methods. Traditional recycling techniques have downsides such as efficiency and environmental drawbacks, even though they do the job. Advancements in materials science are changing the scenario and ushering in a new era of battery recycling, making it more environmentally friendly and economically viable.

Materials science studies the properties of solid materials and the behavior of their constituent materials, which affect said properties and structure. It can play a crucial role in innovating recycling methods and overcoming the limitations of traditional techniques. By understanding the properties of battery materials at a molecular level, new processes are being developed that enhance the recovery of metals from spent batteries.

Integrated carbothermal reduction is a promising recycling technique that uses the physical properties of battery materials to extract them from batteries. It generates no waste and is highly energy efficient compared to the currently prevalent methods.

The magnetic separation technique is another innovation being developed by researchers. This technique enhances the purity of recovered battery materials. Magnetic fields are used to separate battery materials from battery waste, maintaining their structural integrity and functionality.

Hydrometallurgy and pyrometallurgy were the prevalent methods for battery recycling. Pyrometallurgy is highly energy intensive and results in a lot of loss of battery materials as waste. Hydrometallurgy is energy intensive as well and uses a lot of chemicals, meaning there is generation of toxic waste. Hydrometallurgy, the more widely used recycling method, has seen some significant advancements in recent times. The process leeches out metals from battery waste using chemical solutions. Chemical solutions and processes are being innovated to selectively extract valuable metals including lithium, cobalt, and nickel with lower environmental impact. Solvent extraction techniques are also being refined to selectively bind specific metals to enhance the separation of metals from leaching solutions and enhance the purity level of recovered metals.

Advanced materials science in battery recycling enables the consideration of recycling as a method of “mining” batteries. It can solve gaps and pitfalls that are currently faced by battery recycling entities and can offer significant economic and environmental benefits. With increased efficiency and purity of recovered materials, the need for costly and unsustainable virgin mining is reduced.

Extracting a ton of lithium from spent devices requires about 28 tons of end-of-life lithium-ion batteries, compared to 250 tons of ore or 750 tons of brine needed for the extraction of virgin material. It also takes several months to a few years to refine virgin lithium, along with the use of huge amounts of water.

Recycling consumes much fewer resources and takes less time, translating to lower environmental impact. Economically, there is a great case for recycling as recycled materials with high purity levels (and that purity is consistently getting higher thanks to innovations in materials science) are at par with mined materials in terms of price. Companies in North America are scaling their operations, demonstrating that advanced recycling technology is economically viable.

The future of battery recycling is promising and is being spurred by continuous advancements in materials science which are driving the development of more efficient and sustainable processes. As demand for lithium-ion batteries continues to rise, these innovations will play an important role in meeting the world’s energy needs while minimizing environmental impact, promoting circularity of resources as well as energy efficiency.

ess-news.com

About the author:

Manikumar Uppala is the co-founder and chief of industrial engineering at India-based lithium-ion recycling company Metastable Materials |