| | | Disney...Robotic muscle from fabric, and 3D printed skeletal arm//low cost

globalsources.com

Disney makes superhumanly strong robotic arm from fabricLow cost and ease of use may create a wide variety of applications.

June 15, 2015

Share: Facebook Twitter Google Linkedin | Print E-mail

Low cost and ease of use may create a wide variety of applications.

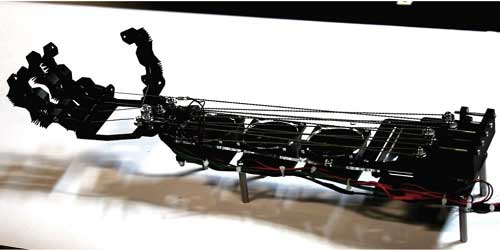

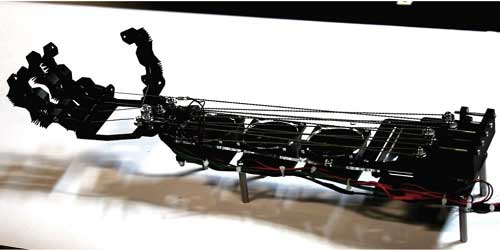

Scientists at Disney have created a process to make robotic "muscles" stronger and cheaper using fabric (Image source: Disney Research)

Disney is not a name you consider at the forefront of robotics research, but scientists at their research division have been experimenting with new and novel ways to make robotic “muscles” stronger, lighter, easier and cheaper to produce. The lead scientists, Michael C. Yip and Gunter Niemeyer, were able to produce a robotic arm that not only is more responsive than existing solutions, but also produces power-to-weight ratio that is even stronger and faster-responding than human muscles.

The muscles are actually conductive sewing thread twisted tightly until it forms coils, building the muscle itself. This thread is essentially the same material found in smartphone-friendly gloves. In fact, one of the most interesting aspects of the whole exercise is that every piece is an off-the-shelf component, the only exception being the frame itself, which was produced using a 3D printer. Their technique produced a muscle that can recover and respond three times faster than an average human skeletal muscle while being 16.5 times stronger than a human muscle fiber of the same weight.

Why is this important to the robotics industry as a whole? While actuators or servos work well, neither existing solution is particularly fluid or fast, and neither can mimic the strength of organic muscles. In addition, the authors note that the muscles are “extremely low-cost and easy to manufacture, making them an accessible technology.” Applications for the technology include Disney mainstay animatronics, prosthetics, and assistive care and DIY robots. |

|