Introduction of honeycomb briquette machine:

1. Honeycomb briquette machine takes the coal powder as raw materials, through mixing, pressing and molding the materials into honeycomb or columnar rod shaped briquettes.

2. It is the mulfunctional machine, and we can change the moulds to manufacture different shapes and sizes of briquettes, like cylindrical shape, square shape, rod shape, flower shape and other shapes, which expand the function of the machine greatly. So our honeycomb briquette machine is an ideal equipment in many industries.

3. Except coal powder, our this honeycomb briquette machine also can press charcoal powder, gypsum powder, sawdust or others into honeycomb or rod cylinder briquettes. And the outlet charcoal briquettes are usually used for barbecue, which is very new hot charcoal in the world.

4. Honeycomb briquette machine, through many times' development, is mainly used for home cooking and keeping warm, chemical industry, refractory industry and others.

1. Shape: the outlet shapes of honeycomb briquette machine can be various honeycomb shape and columnar rod shapes and we can customize different shapes as your needs.

2. Size: the final size is according the machines, and each model of machine has itself minium and maxmium size.

3. Features: the outlet briquettes are of good looking, high density, burning good, long burning, smokeless, etc.

4. Special Briquettes: with our special technology, the final honeycomb briquettes can be easy fire or easy lighting briquettes.

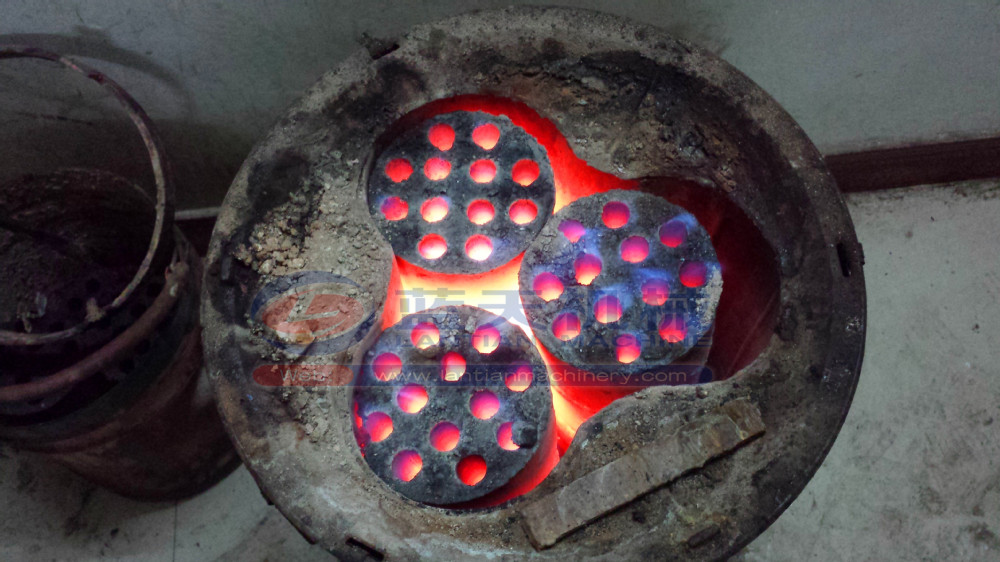

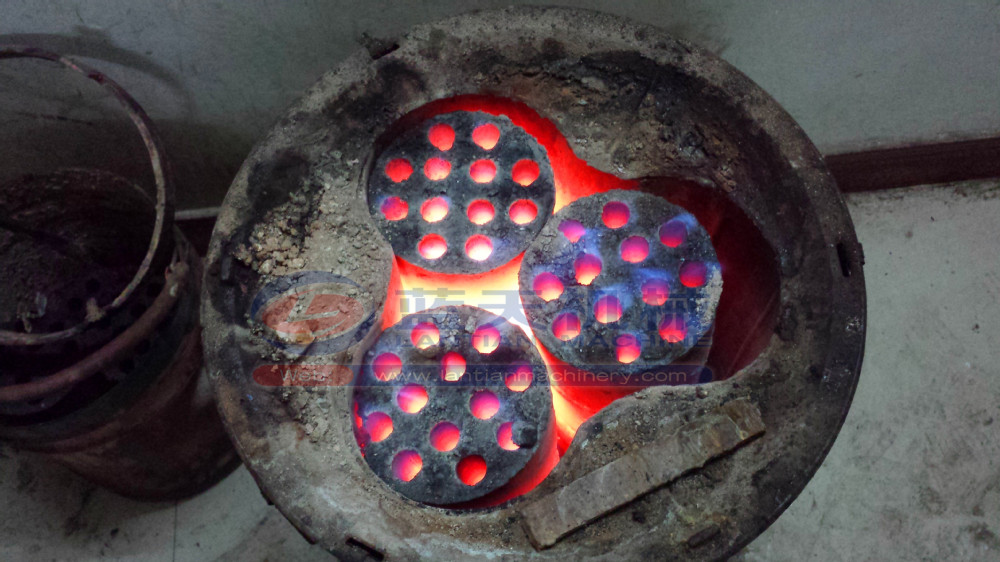

1. In China, a lot of people in village always use this kind of stove for cooking and heating. And the stoves can be different

2. Usually, the stove will be single row with 4pcs honeycomb coal briquettes. The stoves also can be three rows with 12pcs honeycomb coal briquettes.

3. In some restaurant, they usually use square shape honeycomb coal briquettes.

The parameters:

1. It is not that the big honeycomb briquette machine has the big capacity, but the big machine has the big pressure.

2. The capacity is according to the machine you use, and the size of briquettes you are going to make.

3. The big machine has the big pressure, then its lifting and pressing time will be longer.

| Model | Power | Capacity for brick shape | Capacity of rod shape | Outlet size of round | Outlet size of square | Outlet size of rod | Weight | | LTF-140 | 7.5kw | 45 pcs/min | 90-100 pcs/min | =120 mm | =100x100 mm | =50 mm | 1.8ton | | LTF-160 | 7.5kw | 40 pcs/min | 120 pcs/min | =145 mm | =130x130 mm | =50 mm | 2.5ton | | LTF-220 | 15kw | 22-26 pcs/min | 125 pcs/min | =220 mm | =150x150 mm | =50 mm | 3.8ton | | LTF-260 | 11kw | 26 pcs/min | 90-120 pcs/min | =260 mm | =200x200 mm | =50 mm | 3.8ton | | LTF-300 | 15kw | 26 pcs/min | 90-120 pcs/min | =300 mm | =250x250 mm | =50 mm | 4 ton |

The worksite of honeycomb briquette machine:

|