| | | A Stunning Extrapolation Of Tesla's Reported Inefficiency

Aug. 22, 2018 9:56 AM ET | About: Tesla, Inc. (TSLA)

Quoth the Raven

Contrarian, long/short

Contrarian, long/short equity, special situations

Summary

* BI reported on Tuesday that only 14% of Model 3s that rolled off Tesla's line over the last week of June didn't need to be reworked.

* That number pales in comparison to the industry average, which was cited as between 65% and 80%.

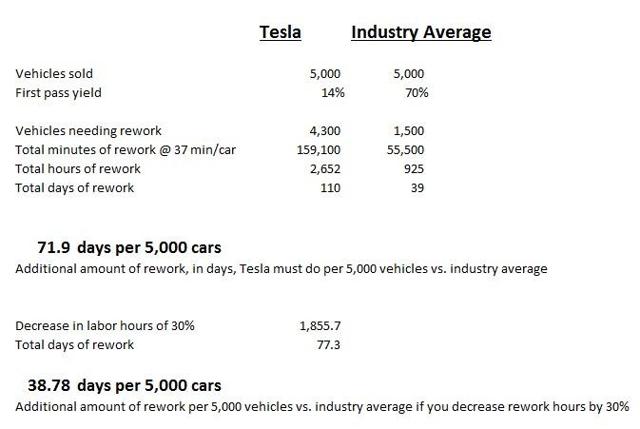

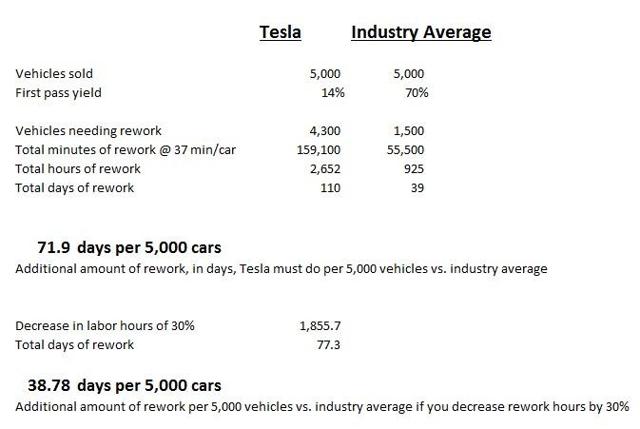

* QTR calculations indicate that at this rate, per every 5,000 vehicles produced, Tesla could be doing an additional 71 days' worth of work than traditional auto manufacturers.

This could be a look into serious inefficiency at the company. I extrapolate the numbers a bit further and make my own estimates.'

(Please note: All calculations in this article are mine alone and are estimates based on

publicly available reported information. Readers are encouraged to review all available data and come up with their own numbers. These are in no way guarantees.)

By now, those following the Tesla ( TSLA) ordeal closely have probably been made aware of an explosive Business Insider expose by Linette Lopez that dropped on Tuesday during the day. Among other things, the BI report stated the following key points:

Of the 5,000 Model 3s that contributed to Tesla's end of June manufacturing target, about 4,300 of them required rework, according to internal documents viewed by Business Insider.Within the auto industry, cars that make it through a manufacturing process without requiring rework are part of a factory or line's "first pass yield (FPY)."That means the factory had a first pass yield for vehicles as low as 14% during the last week of June.An industry expert told Business Insider that good auto plants have a first pass yield of about 80%.A Tesla spokesperson said the number of labor hours required per Model 3 has decreased by almost 30% since last quarter.On its face, these claims are wildly alarming. The fact that Tesla could only produce vehicles at a FPY of 14% that week, when the industry average is between 65% and 80% gives onlookers a stunning view into what appears to be gross inefficiency at the automaker.

The purpose of today’s article isn’t to reiterate everything that BI reported on Tuesday, but rather to address the defense that many Tesla bulls are using. On social media, many bulls are commenting that the report says each rework only took an average of 37 minutes. While that may seem like very little time indeed, when you multiply it by the amount of vehicles that need to be reworked and then you compare it to the automotive industry average, you get a stunning revelation.

By my calculations, and based on using the FPY rate in the BI article, Tesla is spending an extra 71.9 days in work than an average automaker to get 5,000 vehicles on the road. This was what I arrived at when I used a generous 70% FPY for the average automaker, which was stated in the BI article to be 65% to 80%.

Moving off of that worst-case scenario, the BI article also said that a Tesla spokesperson "said the number of labor hours per Model 3 produced has decreased by almost 30% since last quarter."

So, to be fair, I worked that into my model as well. In the case of a 30% reduction in rework hours, my calculations indicate that Tesla would still be spending an extra 37.8 days of work on producing 5,000 vehicles versus the industry average.

If Tesla were to shoot for 20,000 cars per month, these calculations would imply a best case scenario of 155 extra days' worth of work, per month. This amounts to stunning inefficiency. Not only is it indicative of wasted capital, time and resources but it also goes to show that the company's goal of becoming an autonomous manufacturer that blows away the industry with its futuristic production facilities seems to be far from what’s actually happening at the company. If Tesla were to shoot for 20,000 cars per month, these calculations would imply a best case scenario of 155 extra days' worth of work, per month. This amounts to stunning inefficiency. Not only is it indicative of wasted capital, time and resources but it also goes to show that the company's goal of becoming an autonomous manufacturer that blows away the industry with its futuristic production facilities seems to be far from what’s actually happening at the company.

This is a clear indication to me that the company rushed to get these vehicles out and maybe that, despite touting the effectiveness of the tent-produced vehicles, quality could be suffering as a result. The fact that based on these numbers, Tesla is taking at best around 38.7 extra days every 5,000 vehicles to produce something that they can then sell could be just a small sliver into a much larger culture of inefficiency and waste at the company.

This should continue to present a mired picture of not only the culture at the company, but its forecasts for future production targets. What is the point of having 7000 cars a week run off of a line when you need to rework a significant amount of them?

Long investors who are pushing the argument of production numbers for the company should be asking themselves this very question.

Disclosure: I am/we are short TSLA.

I wrote this article myself, and it expresses my own opinions. I am not receiving compensation for it (other than from Seeking Alpha). I have no business relationship with any company whose stock is mentioned in this article.

seekingalpha.com |

|