|

|  |

| We've detected that you're using an ad content blocking browser plug-in or feature. Ads provide a critical source of revenue to the continued operation of Silicon Investor. We ask that you disable ad blocking while on Silicon Investor in the best interests of our community. If you are not using an ad blocker but are still receiving this message, make sure your browser's tracking protection is set to the 'standard' level. |

| Technology Stocks : WDC, NAND, NVM, enterprise storage systems, etc. |

|

| Public ReplyPrvt ReplyMark as Last ReadFile | Previous 10Next 10PreviousNext |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Public ReplyPrvt ReplyMark as Last ReadFile | Previous 10Next 10PreviousNext |

| Home | Hot | SubjectMarks | PeopleMarks | Keepers | Settings |

| Terms Of Use | Contact Us | Copyright/IP Policy | Privacy Policy | About Us | FAQ | Advertise on SI |

| © 2025 Knight Sac Media. Data provided by Twelve Data, Alpha Vantage, and CityFALCON News |

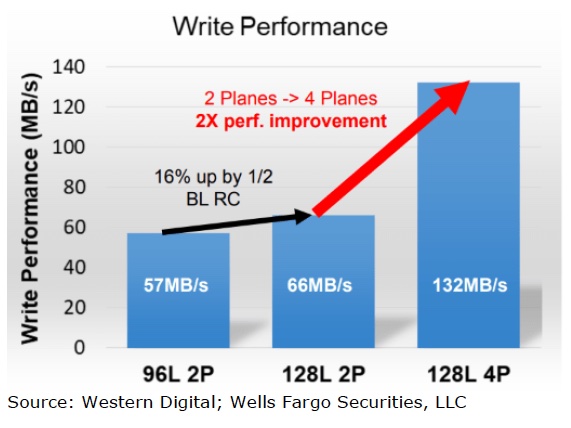

BL is bitline; a line of bits in a die. RC is Resistance-Capacitance. The chart refers to bitlines and their place in the NAND world is explained

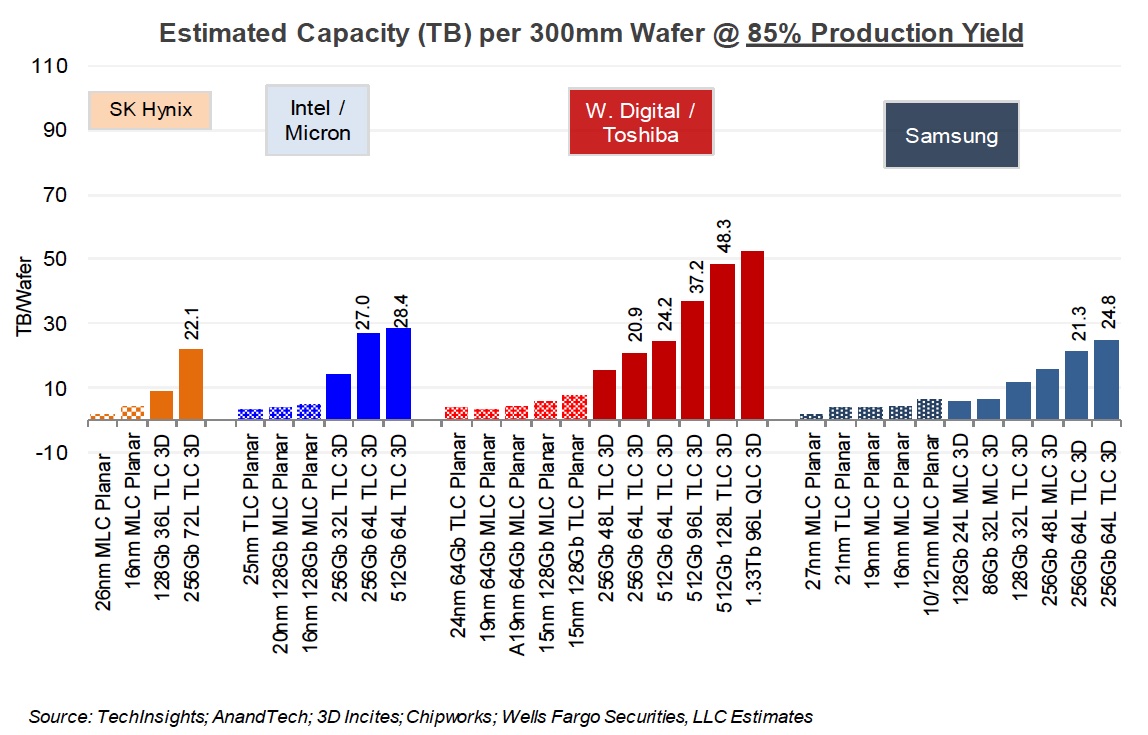

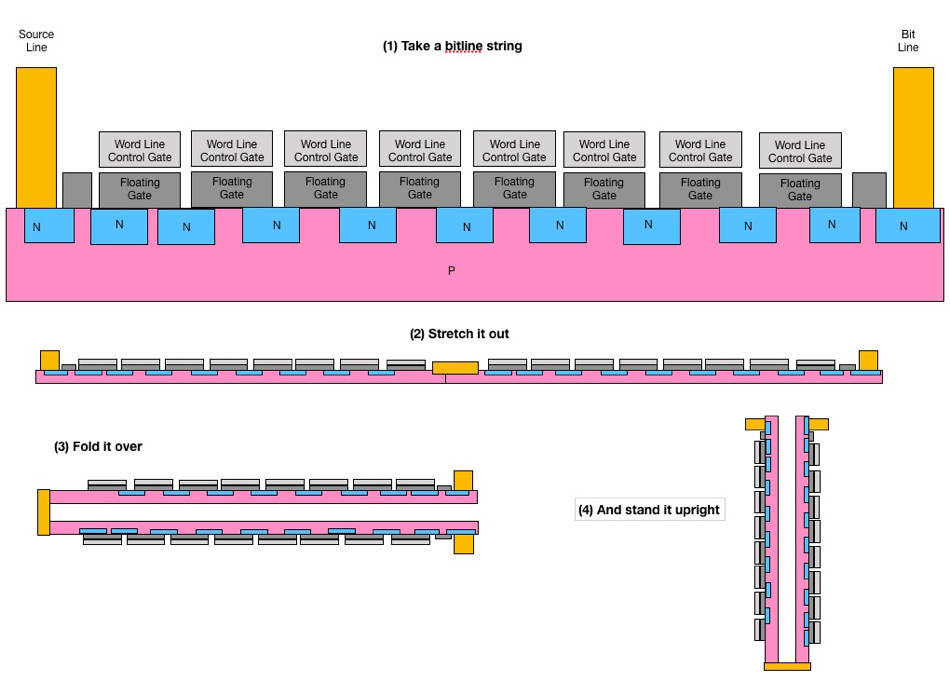

BL is bitline; a line of bits in a die. RC is Resistance-Capacitance. The chart refers to bitlines and their place in the NAND world is explained  How 3D NAND is made conceptually by starting with 2D or planar NAND. The 132MB/sec speed exceeds the 83MB/sec program throughput of a 110+ layer chip from Samsung which can operate at 1.2Gbit/s IO bandwidth and has a 45 microsecond read time.

How 3D NAND is made conceptually by starting with 2D or planar NAND. The 132MB/sec speed exceeds the 83MB/sec program throughput of a 110+ layer chip from Samsung which can operate at 1.2Gbit/s IO bandwidth and has a 45 microsecond read time.