Electrolyser production facility to be offshoot of 10 GW modular green hydrogen plant

A proposed 10 GW renewables-based hydrogen production facility to be developed in the Northern Territory by Climate Impact Corporation will include an upstream Darwin-based electrolyser and atmospheric water generator manufacturing facility.

June 28, 2024 Ev Foley

Hydrogen

Modules & Upstream Manufacturing

Technology and R&D

Australia

Northern Territory

Image: Climate Impact Corporation

Share

The Darwin-headquartered Climate Impact Corporation (CIC) is developing Green Springs, a 10 GW network of renewable hydrogen generation modules capable of producing approximately 500,000 tonnes of green hydrogen annually.

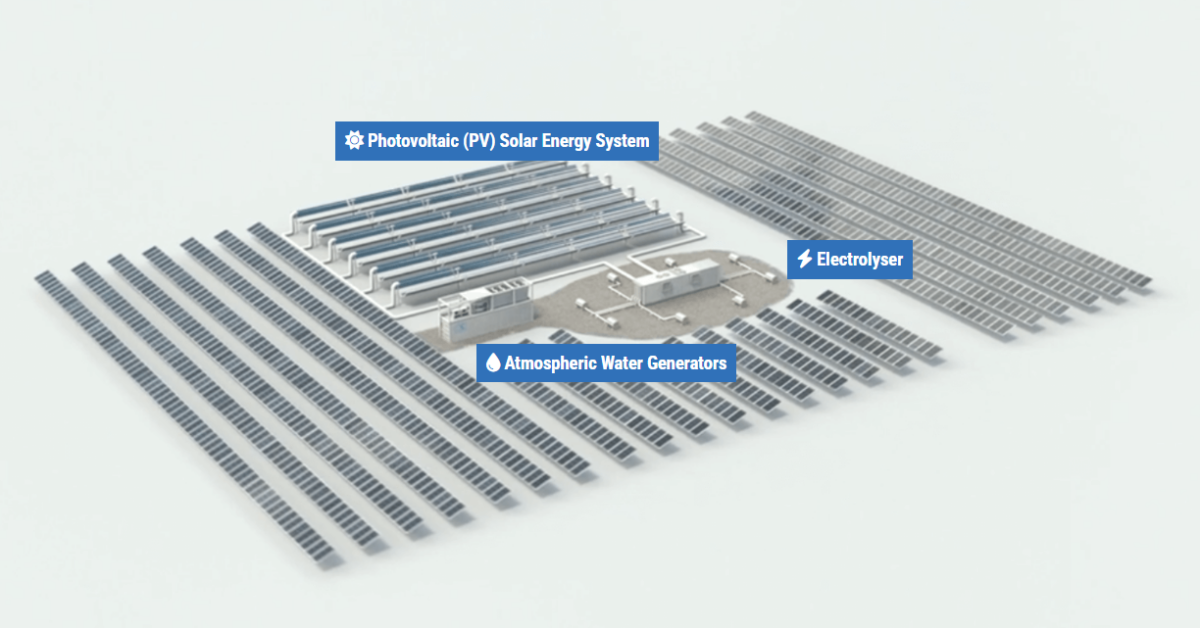

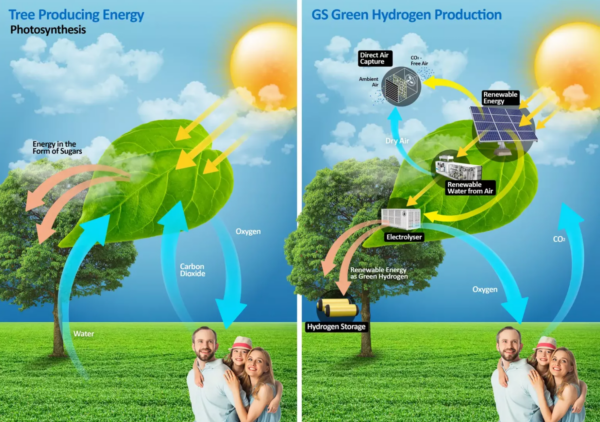

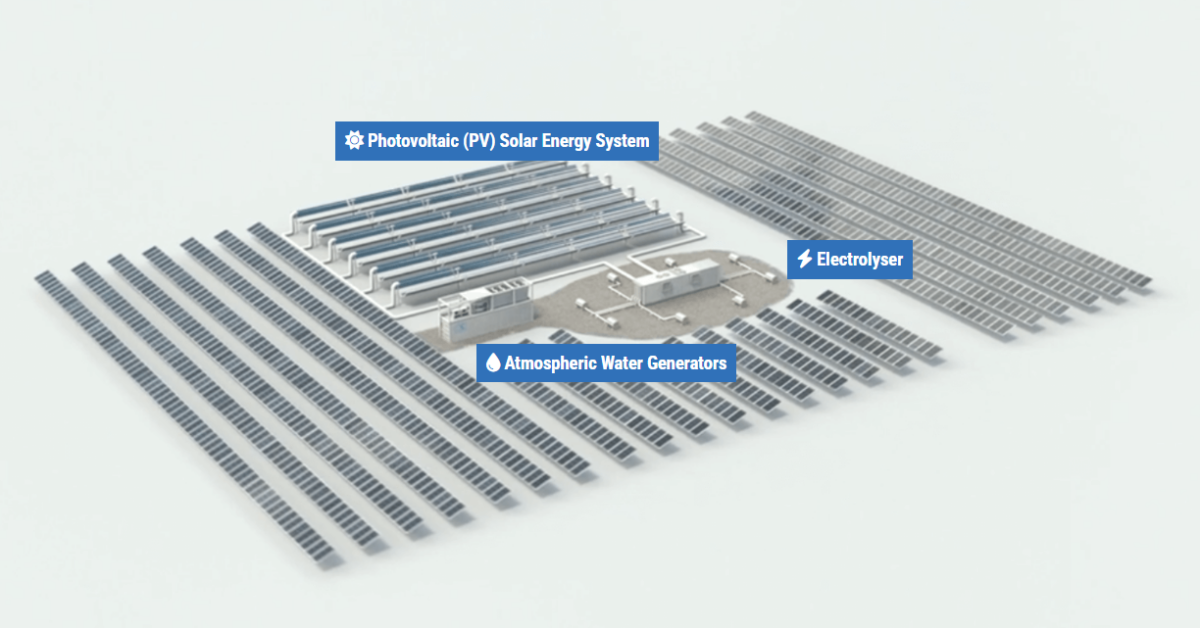

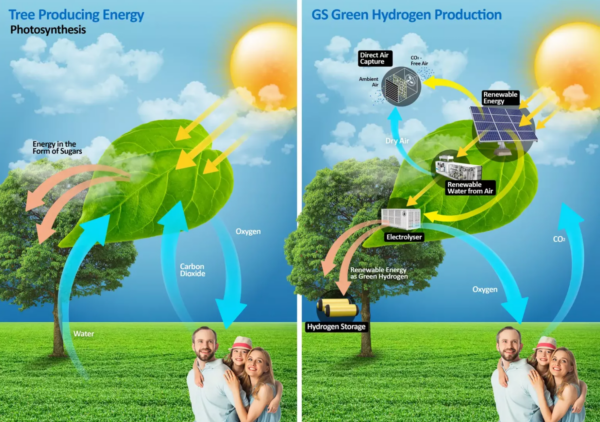

Aiming to achieve a $3.02 ( USD 2 dollars) per kilogram production price, CIC has developed a closed system of modules that each contain solar power generators, atmospheric water generators, electrolysers, and other components that allow for clean hydrogen generation to take place almost anywhere, at any scale.

The project consists of integrated upstream, midstream and downstream components. At an estimated cost of $1 billion, upstream is a 1 GW per annum electrolyser manufacturing facility and an atmospheric water generator manufacturing facility.

The facility is proposed to be located in the Darwin suburb of East Arm, that will supply Green Springs, other domestic hydrogen and energy projects, and for export.

Climate Impact Corporation is callaborating with GE Vernova subsidiary Power Conversion to develop the modules.Image: Climate Impact Corporation

The estimated $8 billion midstream features at full capacity the 10 GW renewable hydrogen production component consisting of a series of modules which include a purpose designed electrolyser and solar system providing power to the electrolyser, ancillary services and direct air capture of CO2.

As well, a concentrated parabolic trough solar thermal heater will provide power to the project and process heat to the atmospheric water generators which produce H2O.

Carbon dioxide would be used in derivatives production facility to produce renewable fuels for hard to abate sectors. Lastly, each module will include an atmospheric water generator.

USA-based GE Vernova’s Paris-headquartered subsidiary, Power Conversion has recently signed a non-binding agreement with CIC to collaborate on the development of the off grid modular green hydrogen production.

Downstream is a hydrogen derivatives production facility, costing around $950 million, and could include e-methanol, e-kerosene and/or fuel ammonia, which can be transported by rail to Darwin Port for shipping.

Green Springs will be located near Tennant Creek, 1,000 km south of Darwin.Image: Climate Impact Corporation

The system’s inclusion of atmospheric water generators with solar power generation means modules are not dependent on ground or town water, taking humidity from the air, an approach CIC describes as revolutionary to producing affordable clean hydrogen.

Atmospheric water generator technology used in the hydrogen production modules eliminate demand for ground or town water but use only energy from the sun and humidity in the air to make hydrogen.

The modules allow for flexible placement on a location and is able to avoid damage to environmental or cultural heritage.

CIC has also been in talks with the South Australian government to discuss the development and manufacture of hydrogen production modules in that state.

pv-magazine-australia.com |