Boeing & Aerospace

Business

Spokane facility gets $48M to boost thermoplastic research for planes

Jan. 25, 2025 at 6:00 am Updated Jan. 25, 2025 at 6:00 am

Marco Salviato, an aeronautics professor at the University of Washington who was involved in the funding proposal for the new Spokane facility, said the U.S. is a leader in thermoset composites but is falling behind in research.(Ken Lambert / The Seattle Times)

By

Lauren Rosenblatt

Seattle Times Amazon reporter

A new Spokane facility hopes to make lighter, more fuel-efficient airplane parts, marking the inland Northwest corridor as a hub for sustainable aviation manufacturing.

Using three giant machines — which all work like waffle irons, stamping and cooking airplane parts instead of breakfast treats — the facility will be a test bed for a new type of material meant to replace aluminum and steel.

That material, thermoplastic composite, is being hailed as the future of sustainable aviation and a crucial component to speeding up airplane production, advocates for the new facility said.

Compared with traditional metals and other alternatives now available, thermoplastic composites are more recyclable, durable and malleable. And the material is lighter, meaning the aircraft built with it will be more fuel-efficient and less costly to fly.

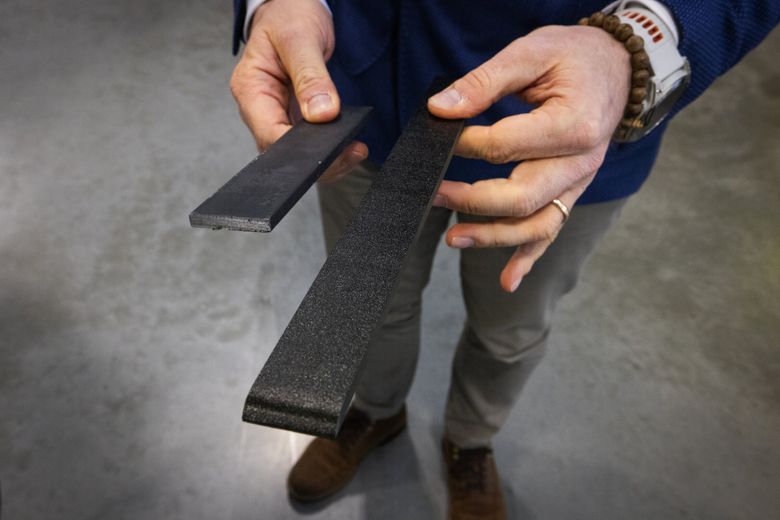

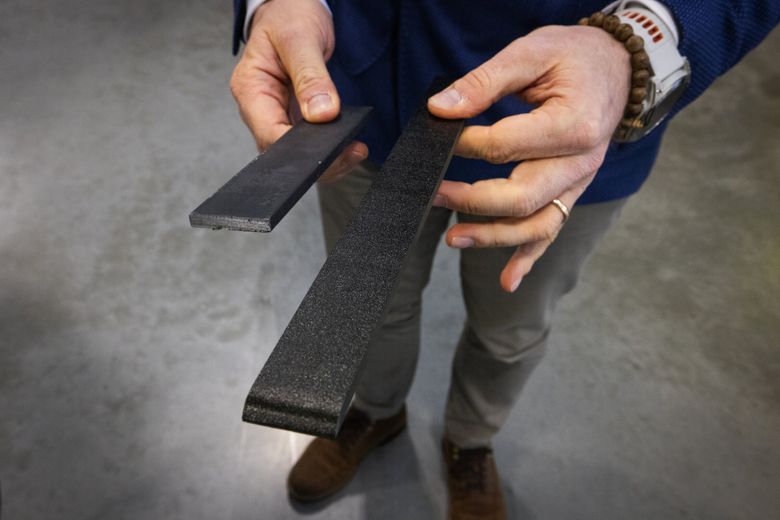

Steel, left, and thermoplastic are compared at University of Washington’s Advanced Composites Center. Manufacturers are already using thermoplastics to make airplane parts, but they’re generally used... (Ken Lambert / The Seattle Times)

“In aviation, saving weight is everything,” said Marco Salviato, an aeronautics professor at the University of Washington who was involved in the funding proposal for the new Spokane facility.

Manufacturers are already using thermoplastics to make airplane parts, but they’re generally used only for small pieces and are slow to build. The Spokane facility is meant to accelerate that work — in terms of the speed of production and the size of what it can create.

1 of 2 | Federal money from the CHIPS and Science Act might be the key to filling the mostly empty former Triumph Composite Systems offices and manufacturing plant in Airway Heights, Wash. (Jesse Tinsley / The Spokesman Review)

The 100,000-square-foot facility — the American Aerospace Materials Manufacturing Center — recently received a $48 million grant through the federal CHIPS and Science Act, passed in 2022 to spur U.S. development of semiconductors and other innovative projects.

The U.S. Department of Commerce chose Spokane as one of 31 federally designated “tech hubs” in 2023 but initially passed it over for CHIPS Act funding. Democratic Sens. Maria Cantwell and Patty Murray announced the funding this month.

Former Spokane-area U.S. Rep. Cathy McMorris Rodgers, a Republican, also helped secure an additional $500 million for the designated “tech hubs” around the country through a year-end military spending bill.

Lawmakers worry the U.S. is at risk of falling behind other countries in developing thermoplastic composite materials. That means Spokane will now be at the center of America’s efforts to catch up.

“The country that figures out how to use advanced materials to increase manufacturing capacity and aircraft fuel efficiency is going to have a huge competitive advantage,” Cantwell said in a written statement announcing the funding. “America is handing the baton to Spokane.”

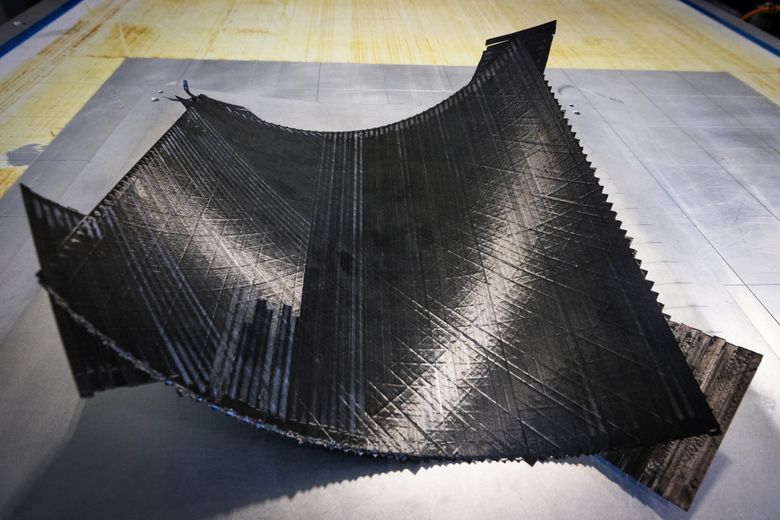

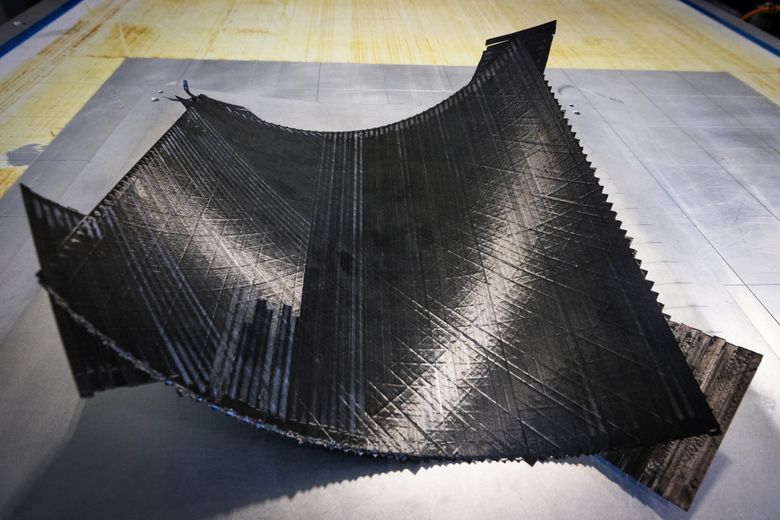

A mold, foreground, to make a Boeing 767 tail part out of composite material was donated by the company to UW’s Advanced Composites Center. (Ken Lambert / The Seattle Times)

“Marvel material”

Salviato, from the University of Washington, called thermoplastic composites a “marvel material.”

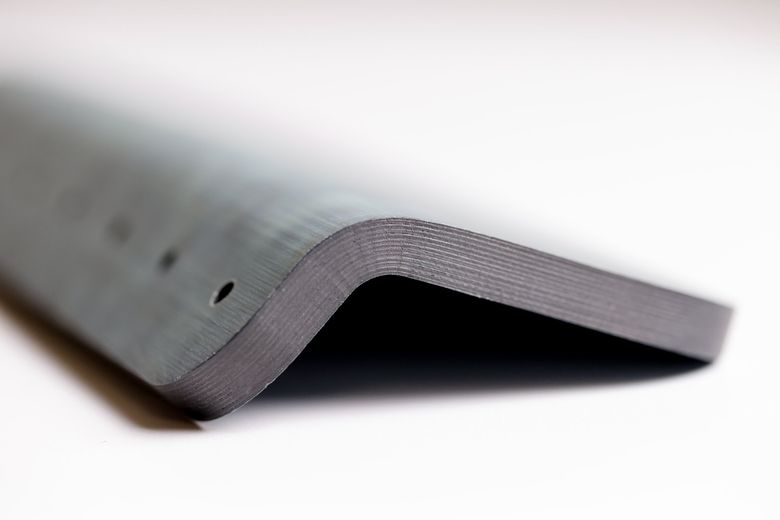

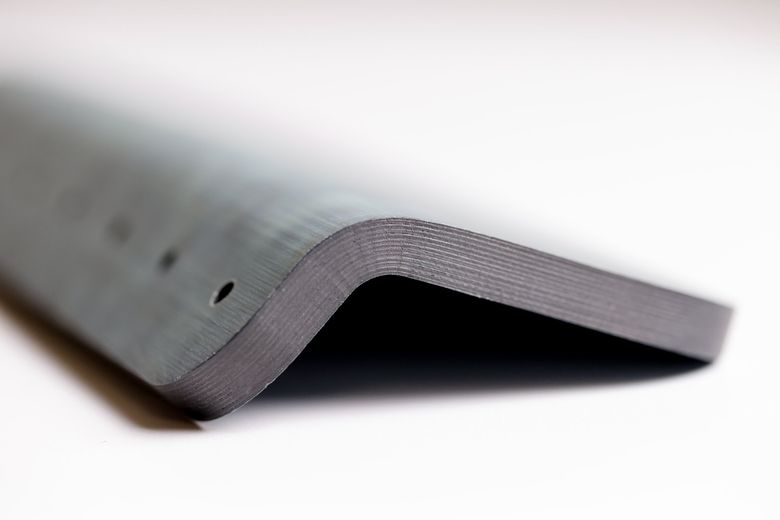

A window frame made from thermoplastic composites could be up to 40% lighter than the same part made from aluminum.

There are two buckets of composite materials meant to replace traditional metals like aluminum and steel: thermosets, which are more common in aviation today, and thermoplastics, which are still being researched.

Thermoset composites have many of the same benefits as thermoplastics but can’t be recycled or welded. Thermoplastics, on the other hand, use a different kind of polymer and can be more easily broken down, which allows them to be recycled, molded during production and reshaped for maintenance and repairs.

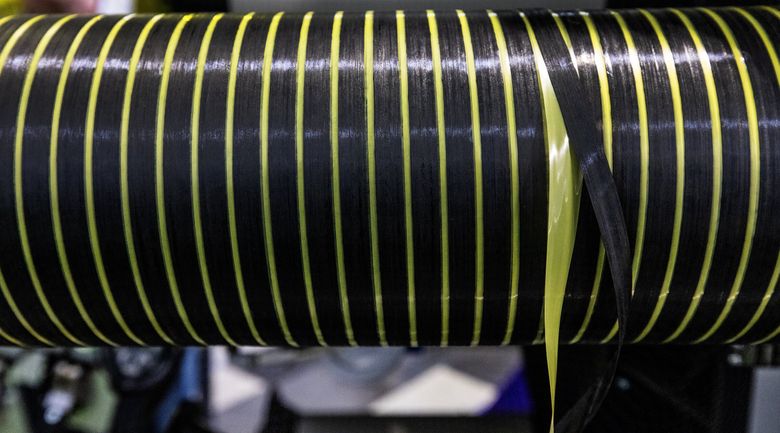

1 of 2 | A composite material sample made by a robot is seen at the University of Washington’s Advanced Composites Center. (Ken Lambert / The Seattle Times)

Salviato compared the two types of materials to more breakfast foods. Thermosets are like making scrambled eggs; once they’re cooked, there’s no going back. Thermoplastics are like butter; they can continuously be changed, broken down and reformed.

Thermoplastics are also faster to make, cutting production time from hours to minutes. And the material doesn’t have an expiration date. Thermosets have to be stored in a freezer, or they’ll break down at room temperature after about 28 days, Salviato said. Even cooled, the material only lasts six months.

Right now, thermosets make up about 80% of the composite material in use in the aerospace industry, while thermoplastics make up about 20%. But, because thermoplastics are faster to make, the material will be crucial to the future of aviation, Salviato said.

Aerospace manufacturers have been researching thermoplastic composites for at least 40 years, said John Busel, who leads the Composites Growth Initiative at the American Composites Manufacturers Association. Busel was working on thermoplastic composites at Boeing in the 1980s.

1 of 3 | A close-up of an aircraft window frame made of thermoplastic composite is seen at a facility in Kent. (Karen Ducey / The Seattle Times)

The material first appeared on planes in service in the 1990s and investment ramped up in the 2000s, Busel continued. Boeing’s 787 and its rival Airbus’ A350, both released in the early 2010s,were “major steps” forward in applying new composite material, thermosets and thermoplastics, Busel said. Roughly half of the 787 is made of composites, he said.

But the progression won’t be linear. Not every new plane model will include more composites, Busel said. Thermoplastic composites, particularly, are still costly and difficult to produce at scale.

Most Read Business Stories Inside the test bed

The new facility in Spokane hopes to be the premier U.S. site for experimenting and validating airplane parts built with thermoplastic composites. Manufacturers will then be able to bring what they learn back to their own production line.

The goal is to “take it from a pilot to scale up to production,” said Busel, who works with some of the more than 50 stakeholders who helped make the new facility possible.

These machines “are very sophisticated and do a lot of things that manual labor could not do repeatedly,” Busel said. “That is the key. How can we make this structure and repeat it, and know exactly what it’s going to be for the first unit to unit 5,000?”

The three presses to be built at the facility, which was built to make airplane parts for Boeing and later sold to a Boeing supplier, use a combination of heat and pressure to fuse the thermoplastic composite material into new parts. Just like pouring batter into a waffle maker, Salviato said, the unconsolidated material will fill every crevice in the mold.

“What you end up getting is a product that is very close to its final shape,” he said. “So you minimize the extra machining that you would normally do.”

The Wing Maker will be an 800-ton press specialized for creating wing support beams. The Development Press will be a 1,000-ton shuttle press used for rapid testing. And the Giant Press will be a 5,000-ton machine that shapes massive aircraft parts.

The Giant Press will be the equivalent of applying the weight of 1,600 pickup trucks, Salviato said.

The center, which will open in 2026 and be fully operational by 2027, will also train the aerospace workforce on how to use these types of machines.

Cantwell hopes the new center will make Spokane a “cluster of that kind of expertise,” attracting more companies to invest in the region.

“Once you show the technology proof of concept then it will be working with different manufacturers on how they want to adopt that,” Cantwell said in an interview.

Then, Spokane can turn to the next innovation, she said. The goal is to focus on “those areas of expertise that manufacturers can’t figure out on their own.”

The University of Washington’s Advanced Composites Center is located in a Sand Point building that dates back to the early decades of the last century. Sen. Maria Cantwell recently secured funding for a new... (Ken Lambert / The Seattle Times)

Complementary research

In Seattle, Salviato and other UW researchers have already been testing how to create and use thermoplastic composite material in aviation.

In a 16,000-square-foot warehouse in Magnuson Park, UW’s Advanced Center for Composites sits on the same ground that was once the launchpad for the first flight around the world in 1924. The center, focused on composites research, opened in 2022.

Inside, Salviato and his team are working on how to use both thermoset and thermoplastic composites to build intricate airplane parts.

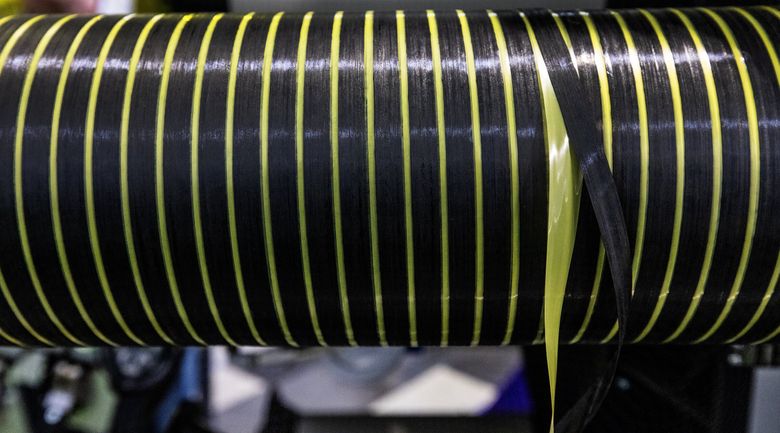

One robot lays carbon fiber composite material eight spools at a time and then points a laser to fuse it together. Another machine runs an ultrasound over newly created composite material to detect flaws. Down the line, UW hopes to use machine learning and artificial intelligence to automate the analysis of that data, making it easier to spot defects.

Another robot is speeding up the process for testing new material for certification by the Federal Aviation Administration. Rather than manually running hundreds of tests, the robot can keep moving materials through the series of evaluations 24/7.

A device uses an ultrasound to scan for defects in composite materials being tested at the University of Washington’s Advanced Composites Center. (Ken Lambert / The Seattle Times)

Salviato sees the work as a complement to the Spokane tech hub. While the new facility will build massive parts at a quick pace and large scale, the UW research center builds more complex structures and is fine-tuning the intricate parts of the process.

The thermoplastic composites that come out of the new facility, for example, will need to be tested for FAA certification and could benefit from the robotic testing happening at UW. A new machine scheduled to come to UW’s center by the end of the year would allow manufacturers to 3D print airplane parts like stiffeners or air ducts directly on top of the large pieces that are produced in Spokane.

Salviato moved from Italy to the U.S. because in the early 2000s this was the best place to study composite materials. The U.S. still is a leader in thermoset composites, he said, but it is falling behind other countries in thermoplastic research.

He hopes the combination of UW’s research, Spokane’s new testing facility and government investment in the region will put the U.S. and Washington back on top.

Lauren Rosenblatt: 206-464-2927 or lrosenblatt@seattletimes.com.

seattletimes.com |