Bob pays more attention to the news than I do. I just have a small track position now. It looks like COHU is approaching my original entry point from years ago at $18. I may re-enter into a large position at that point.

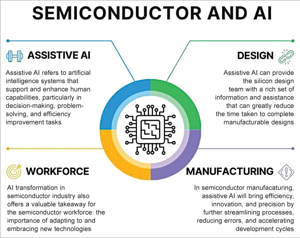

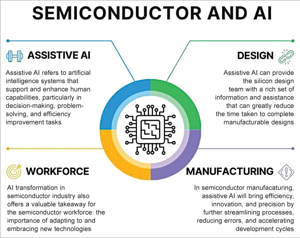

Here is some background on what Tignis does from Perplexity. My impression is the AI assisted inspection is a significant improvement to the semiconductor test process, but I am not sure it is a game changer. Though the assert below from the Perplexity.ai result indicates a "Tignis' AI solutions can reduce the time from device design to high-volume production by half or even a quarter"

>>>>>>>>>>>>>>>>>

What does the company Tignis do and what is it competitive moat

Share

What does the company Tignis do and what is it competitive moat?

Edit Query

Sources

Tignis, a Technology Innovator in AI Process Control Solutions for ...

businesswire

How an Economic Moat Provides a Competitive Advantage

investopedia

[PDF] Morningstar's Five Sources of Moat - VanEck

vaneck

Show all

Answer

Tignis specializes in AI-powered process control solutions for the semiconductor manufacturing industry 1 7. The company's core offerings include:- PAICe Product Suite: Launched in 2021, this suite accelerates the building, validation, and deployment of physics-driven, machine learning-enabled solutions in semiconductor manufacturing 1.

- PAICe Monitor: An AI-driven anomaly detection and predictive maintenance platform that enables quick deployment of machine learning for deep analysis and prediction modeling 4.

- PAICe Maker: An AI-driven advanced process control solution that automatically adjusts for process drift over time, reducing maintenance costs and process variability 4.

Tignis' competitive moat is built on several factors:- Technological Edge: Tignis has developed proprietary technology, including a patent-pending domain-specific scripting language called Digital Twin Query Language (DTQL) 4. This technology allows users to manage complex data cleaning and analytics tasks without requiring data science experience.

- Specialized Focus: The company is hyper-focused on AI process control for semiconductor manufacturing, giving it deep industry expertise 1.

- Partnerships: Tignis' technologies are in use by multiple top-five global semiconductor equipment companies, with contracts in place for next-generation semiconductor manufacturing tools 1.

- Unique Approach: Tignis combines physics insights with advanced AI and ML data science, allowing customers to explore future equipment operations in previously unobserved modes 7.

- Efficiency Gains: The company's solutions offer significant efficiency improvements, with surrogate machine learning models that are more accurate and up to one million times faster than physics-based simulations 5.

These factors contribute to creating barriers to entry and switching costs for customers, potentially providing Tignis with a sustainable competitive advantage in the rapidly evolving semiconductor industry.

Share

Rewrite

Related

How does Tignis' AI process control technology improve semiconductor manufacturing

What are the key features of Tignis' PAICe Product Suite

How does Tignis' technology compare to other AI solutions in the semiconductor industry

What makes Tignis' low-code language proprietary and effective

How does Tignis ensure the successful implementation of its AI process control solutions

View More

How does Tignis' AI process control technology improve semiconductor manufacturing

Edit Query

Sources

Tackling Variability With AI-based Process Control

semiengineering

Tignis, a Technology Innovator in AI Process Control Solutions for ...

businesswire

[PDF] Benefits of Implementing AI/ML Controllers for Semiconductor ...

csmantech

Show all

Answer

Tignis' AI process control technology significantly improves semiconductor manufacturing in several ways:- Accelerated Process Development: Tignis' AI solutions can reduce the time from device design to high-volume production by half or even a quarter 1. This acceleration is crucial in an industry where time-to-market is critical.

- Enhanced Process Control: The PAICe Product Suite enables autonomous control of semiconductor manufacturing tools by modulating recipe parameters in response to sensor readings and metrology 1. This level of control allows for more precise and consistent manufacturing processes.

- Improved Efficiency and Quality: AI process control accelerates semiconductor process development, improves efficiency and quality, and enables manufacturing technologies that were previously too complex to model 2.

- Real-time Adaptive Control: PAICe Maker dramatically speeds up simulations, allowing semiconductor manufacturers to adaptively control complex OEM machinery in real-time 2. This capability is particularly valuable for managing processes with numerous interdependent parameters.

- Reduced Variability: Tignis' AI-based process control helps tackle equipment variability and corrects for process drift over time 1. This leads to more consistent output and higher yields.

- Multi-Tool Co-Optimization: Tignis' AI controllers can account for a wide array of environmental and upstream parameters to co-optimize multiple tools in series, rather than controlling each tool in isolation 3. This holistic approach leads to better overall process optimization.

- Predictive Maintenance: The technology enables predictive maintenance, helping to identify potential issues before they cause production disruptions 5.

- Exploration of Future States: Tignis' unique physics-driven AI models allow manufacturers to explore how their equipment will operate in previously unobserved modes, providing valuable insights for process optimization 5.

By combining physics insights with advanced AI and ML data science, Tignis' technology enables semiconductor manufacturers to produce smaller and more complex chips, achieve faster time to market, improve yields, and reduce operational costs 2.

Share

Rewrite

Related

How does Tignis' AI technology reduce equipment variability in semiconductor manufacturing

What role does machine learning play in Tignis' AI process control solutions

How does Tignis' AI technology accelerate the high-volume manufacturing of semiconductors

What are the benefits of using Tignis' AI process control for next-generation semiconductor tools

How does Tignis' AI technology help in identifying integration issues in semiconductor manufacturing

How does Tignis' AI technology reduce equipment variability in semiconductor manufacturing

Edit Query

Sources

Navigating The Talent Crunch: AI Solutions For A Thriving ...

semiengineering

Tignis - Semiconductor Engineering

semiengineering

Tignis Raises $7.2M for AI Semiconductor Solutions | Built In Seattle

builtinseattle

Show all

Answer

<div class="prose text-pretty dark:prose-invert inline leading-normal break-words min-w-0 [word-break:break-word]" style="box-sizing: border-box; border: 0px solid rgb(229, 231, 235); scrollbar-color: auto; scrollbar-width: auto; --tw-border-spacing-x: 0; --tw-border-spacing-y: 0; --tw-translate-x: 0; --tw-translate-y: 0; --tw-rotate: 0; --tw-skew-x: 0; --tw-skew-y: 0; --tw-scale-x: 1; --tw-scale-y: 1; --tw-pan-x: ; --tw-pan-y: ; --tw-pinch-zoom: ; --tw-scroll-snap-strictness: proximity; --tw-gradient-from-position: ; --tw-gradient-via-position: ; --tw-gradient-to-position: ; --tw-ordinal: ; --tw-slashed-zero: ; --tw-numeric-figure: ; --tw-numeric-spacing: ; --tw-numeric-fraction: ; --tw-ring-inset: ; --tw-ring-offset-width: 0px; --tw-ring-offset-color: #fff; --tw-ring-color: rgba(59,130,246,.5); --tw-ring-offset-shadow: 0 0 #0000; --tw-ring-shadow: 0 0 #0000; --tw-shadow: 0 0 #0000; --tw-shadow-colored: 0 0 #0000; --tw-blur: ; --tw-brightness: ; --tw-contrast: ; --tw-grayscale: ; --tw-hue-rotate: ; --tw-invert: ; --tw-saturate: ; --tw-sepia: ; --tw-drop-shadow: ; --tw-backdrop-blur: ; --tw-backdrop-brightness: ; --tw-backdrop-contrast: ; --tw-backdrop-grayscale: ; --tw-backdrop-hue-rotate: ; --tw-backdrop-invert: ; --tw-backdrop-opacity: ; --tw-backdrop-saturate: ; --tw-backdrop-sepia: ; --tw-contain-size: ; --tw-contain-layout: ; --tw-contain-paint: ; --tw-contain-style: ; color: var(--tw-prose-body); max-width: 65ch; --tw-prose-body: oklch(var(--text-color-100)/); --tw-prose-headings: oklch(var(--text-color-100)/); --tw-prose-lead: oklch(var(--text-color-100)/); --tw-prose-links: oklch(var(--text-color-100)/); --tw-prose-bold: oklch(var(--text-color-100)/); --tw-prose-counters: oklch(var(--text-color-200)/); --tw-prose-bullets: oklch(var(--text-color-200)/); --tw-prose-hr: oklch(var(--border-color-100)/); --tw-prose-quotes: oklch(var(--text-color-100)/); --tw-prose-quote-borders: oklch(var(--border-color-100)/); --tw-prose-captions: oklch(var(--text-color-200)/); --tw-prose-kbd: #111827; --tw-prose-kbd-shadows: 17 24 39; --tw-prose-code: oklch(var(--text-color-100)/); --tw-prose-pre-code: oklch(var(--text-color-100)/); --tw-prose-pre-bg: oklch(var(--background-color-200)/); --tw-prose-th-borders: oklch(var(--border-color-100)/); --tw-prose-td-borders: oklch(var(--border-color-100)/); --tw-prose-invert-body: oklch(var(--dark-text-color-100)/); --tw-prose-invert-headings: oklch(var(--dark-text-color-100)/); --tw-prose-invert-lead: oklch(var(--dark-text-color-100)/); --tw-prose-invert-links: oklch(var(--dark-text-color-100)/); --tw-prose-invert-bold: oklch(var(--dark-text-color-100)/); --tw-prose-invert-counters: oklch(var(--dark-text-color-200)/); --tw-prose-invert-bullets: oklch(var(--dark-text-color-200)/); --tw-prose-invert-hr: oklch(var(--dark-border-color-100)/); --tw-prose-invert-quotes: oklch(var(--dark-text-color-100)/); --tw-prose-invert-quote-borders: oklch(var(--dark-border-color-100)/); --tw-prose-invert-captions: oklch(var(--dark-text-color-100)/); --tw-prose-invert-kbd: #fff; --tw-prose-invert-kbd-shadows: 255 255 255; --tw-prose-invert-code: oklch(var(--dark-text-color-100)/); --tw-prose-invert-pre-code: oklch(var(--dark-text-color-100)/); --tw-prose-invert-pre-bg: oklch(var(--dark-background-color-200)/); --tw-prose-invert-th-borders: oklch(var(--dark-border-color-100)/); --tw-prose-invert-td-borders: oklch(var(--dark-border-color-100)/); font-size: 1rem; line-height: 1.5; display: inline; min-width: 0px; text-wrap: pretty; overflow-wrap: break-word; word-break: break-word;">Tignis' AI technology reduces equipment variability in semiconductor manufacturing through several key mechanisms:- Real-time Adaptive Control: PAICe Maker enables semiconductor manufacturers to adaptively control complex OEM machinery in real-time, allowing for immediate adjustments to maintain consistency across equipment 4.

- Automatic Process Drift Correction: The AI-driven advanced process control solution automatically adjusts for process drift over time, reducing process variability and maintenance costs 5.

- Predictive Maintenance: PAICe Monitor uses AI-driven anomaly detection to predict and prevent potential issues before they occur, ensuring tool availability is maximized and reducing unexpected variations in equipment performance 1.

- Deep Analysis and Prediction Modeling: The AI technology enables deep analysis and prediction modeling that surpasses traditional methods, allowing for more precise control of manufacturing processes 5.

- Multi-variable Optimization: Tignis' AI can identify complex and non-linear multivariate relationships between process variables and target metrics, automatically generating analytics to monitor for complex process deviations 2.

- Simulation and Optimization: The technology dramatically speeds up simulations, enabling manufacturers to optimize processes and reduce variability across different equipment 4.

- Continuous Monitoring and Adjustment: By continuously monitoring and optimizing the manufacturing process, Tignis' AI ensures that errors are minimized and faulty products are avoided, leading to more consistent output 3.

These AI-driven capabilities work together to significantly reduce equipment variability, resulting in improved efficiency, higher quality, and more consistent semiconductor manufacturing processes.

Share

Rewrite

Related

How does Tignis' AI technology predict and prevent potential issues in semiconductor manufacturing

What specific AI algorithms does Tignis use to optimize semiconductor manufacturing processes

How does Tignis' AI technology contribute to reducing waste in semiconductor manufacturing

What are the main challenges Tignis' AI technology addresses in semiconductor manufacturing

How does Tignis' AI technology enhance tool availability in semiconductor manufacturing

What are the main challenges Tignis' AI technology addresses in semiconductor manufacturing

Edit Query

Sources

Navigating The Talent Crunch: AI Solutions For A Thriving ...

semiengineering

[PDF] AI Process Control Platform Enabling Next Generation Technology

tignis

Tackling Variability With AI-based Process Control

semiengineering

Show all

Answer

<div class="prose text-pretty dark:prose-invert inline leading-normal break-words min-w-0 [word-break:break-word]" style="box-sizing: border-box; border: 0px solid rgb(229, 231, 235); scrollbar-color: auto; scrollbar-width: auto; --tw-border-spacing-x: 0; --tw-border-spacing-y: 0; --tw-translate-x: 0; --tw-translate-y: 0; --tw-rotate: 0; --tw-skew-x: 0; --tw-skew-y: 0; --tw-scale-x: 1; --tw-scale-y: 1; --tw-pan-x: ; --tw-pan-y: ; --tw-pinch-zoom: ; --tw-scroll-snap-strictness: proximity; --tw-gradient-from-position: ; --tw-gradient-via-position: ; --tw-gradient-to-position: ; --tw-ordinal: ; --tw-slashed-zero: ; --tw-numeric-figure: ; --tw-numeric-spacing: ; --tw-numeric-fraction: ; --tw-ring-inset: ; --tw-ring-offset-width: 0px; --tw-ring-offset-color: #fff; --tw-ring-color: rgba(59,130,246,.5); --tw-ring-offset-shadow: 0 0 #0000; --tw-ring-shadow: 0 0 #0000; --tw-shadow: 0 0 #0000; --tw-shadow-colored: 0 0 #0000; --tw-blur: ; --tw-brightness: ; --tw-contrast: ; --tw-grayscale: ; --tw-hue-rotate: ; --tw-invert: ; --tw-saturate: ; --tw-sepia: ; --tw-drop-shadow: ; --tw-backdrop-blur: ; --tw-backdrop-brightness: ; --tw-backdrop-contrast: ; --tw-backdrop-grayscale: ; --tw-backdrop-hue-rotate: ; --tw-backdrop-invert: ; --tw-backdrop-opacity: ; --tw-backdrop-saturate: ; --tw-backdrop-sepia: ; --tw-contain-size: ; --tw-contain-layout: ; --tw-contain-paint: ; --tw-contain-style: ; color: var(--tw-prose-body); max-width: 65ch; --tw-prose-body: oklch(var(--text-color-100)/); --tw-prose-headings: oklch(var(--text-color-100)/); --tw-prose-lead: oklch(var(--text-color-100)/); --tw-prose-links: oklch(var(--text-color-100)/); --tw-prose-bold: oklch(var(--text-color-100)/); --tw-prose-counters: oklch(var(--text-color-200)/); --tw-prose-bullets: oklch(var(--text-color-200)/); --tw-prose-hr: oklch(var(--border-color-100)/); --tw-prose-quotes: oklch(var(--text-color-100)/); --tw-prose-quote-borders: oklch(var(--border-color-100)/); --tw-prose-captions: oklch(var(--text-color-200)/); --tw-prose-kbd: #111827; --tw-prose-kbd-shadows: 17 24 39; --tw-prose-code: oklch(var(--text-color-100)/); --tw-prose-pre-code: oklch(var(--text-color-100)/); --tw-prose-pre-bg: oklch(var(--background-color-200)/); --tw-prose-th-borders: oklch(var(--border-color-100)/); --tw-prose-td-borders: oklch(var(--border-color-100)/); --tw-prose-invert-body: oklch(var(--dark-text-color-100)/); --tw-prose-invert-headings: oklch(var(--dark-text-color-100)/); --tw-prose-invert-lead: oklch(var(--dark-text-color-100)/); --tw-prose-invert-links: oklch(var(--dark-text-color-100)/); --tw-prose-invert-bold: oklch(var(--dark-text-color-100)/); --tw-prose-invert-counters: oklch(var(--dark-text-color-200)/); --tw-prose-invert-bullets: oklch(var(--dark-text-color-200)/); --tw-prose-invert-hr: oklch(var(--dark-border-color-100)/); --tw-prose-invert-quotes: oklch(var(--dark-text-color-100)/); --tw-prose-invert-quote-borders: oklch(var(--dark-border-color-100)/); --tw-prose-invert-captions: oklch(var(--dark-text-color-100)/); --tw-prose-invert-kbd: #fff; --tw-prose-invert-kbd-shadows: 255 255 255; --tw-prose-invert-code: oklch(var(--dark-text-color-100)/); --tw-prose-invert-pre-code: oklch(var(--dark-text-color-100)/); --tw-prose-invert-pre-bg: oklch(var(--dark-background-color-200)/); --tw-prose-invert-th-borders: oklch(var(--dark-border-color-100)/); --tw-prose-invert-td-borders: oklch(var(--dark-border-color-100)/); font-size: 1rem; line-height: 1.5; display: inline; min-width: 0px; text-wrap: pretty; overflow-wrap: break-word; word-break: break-word;">Tignis' AI technology addresses several critical challenges in semiconductor manufacturing:- Labor Shortage: The semiconductor industry faces a severe talent crunch, with a lack of skilled workers. Tignis' AI solutions help bridge this gap by automating complex processes and enabling existing staff to be more efficient 1 5.

- Process Variability: AI-powered process control significantly reduces equipment variability and corrects for process drift over time, ensuring more consistent output and higher yields 2 3.

- Time-to-Market: Tignis' AI technology can reduce the time from device design to high-volume production by half or even a quarter, accelerating the overall manufacturing process 3.

- Complex Process Control: The AI enables control of systems with millions of complex measured properties while accounting for non-linear interactions, something previously impossible with traditional methods 2.

- Predictive Maintenance: Tignis' AI systems can predict and prevent potential issues before they occur, maximizing tool availability and reducing unexpected downtime 1 2.

- Efficiency and Cost: By optimizing processes and reducing waste, Tignis' AI solutions improve overall equipment efficiency and lower the cost of ownership for semiconductor manufacturers 2.

- Adaptive Control: The AI continuously learns and improves as data is collected, allowing for real-time adjustments to compensate for simulation model errors, environmental changes, product changes, or equipment drift 2.

- Virtual Metrology: Built-in virtual metrology enables downstream process modification for better yield, further enhancing production quality 2.

By addressing these challenges, Tignis' AI technology is helping semiconductor manufacturers improve efficiency, quality, and competitiveness in an increasingly complex and demanding industry.

Share

Rewrite

Related

How does Tignis' AI technology handle process drift in semiconductor manufacturing

What impact does Tignis' AI technology have on the overall efficiency of semiconductor manufacturing

How does Tignis' AI technology integrate with existing semiconductor manufacturing equipment

What are the long-term benefits of implementing Tignis' AI technology in semiconductor manufacturing

How does Tignis' AI technology improve the yield of semiconductor production

How does Tignis' AI technology improve the yield of semiconductor production

Edit Query

Sources

AI Process Control Platform Enabling Next Generation …

tignis

Tignis Raises $7.2M for AI Semiconductor Solutions

builtinseattle

Tackling Variability With AI-based Process Control

semiengineering

Show all

Answer

<div class="prose text-pretty dark:prose-invert inline leading-normal break-words min-w-0 [word-break:break-word]" style="box-sizing: border-box; border: 0px solid rgb(229, 231, 235); scrollbar-color: auto; scrollbar-width: auto; --tw-border-spacing-x: 0; --tw-border-spacing-y: 0; --tw-translate-x: 0; --tw-translate-y: 0; --tw-rotate: 0; --tw-skew-x: 0; --tw-skew-y: 0; --tw-scale-x: 1; --tw-scale-y: 1; --tw-pan-x: ; --tw-pan-y: ; --tw-pinch-zoom: ; --tw-scroll-snap-strictness: proximity; --tw-gradient-from-position: ; --tw-gradient-via-position: ; --tw-gradient-to-position: ; --tw-ordinal: ; --tw-slashed-zero: ; --tw-numeric-figure: ; --tw-numeric-spacing: ; --tw-numeric-fraction: ; --tw-ring-inset: ; --tw-ring-offset-width: 0px; --tw-ring-offset-color: #fff; --tw-ring-color: rgba(59,130,246,.5); --tw-ring-offset-shadow: 0 0 #0000; --tw-ring-shadow: 0 0 #0000; --tw-shadow: 0 0 #0000; --tw-shadow-colored: 0 0 #0000; --tw-blur: ; --tw-brightness: ; --tw-contrast: ; --tw-grayscale: ; --tw-hue-rotate: ; --tw-invert: ; --tw-saturate: ; --tw-sepia: ; --tw-drop-shadow: ; --tw-backdrop-blur: ; --tw-backdrop-brightness: ; --tw-backdrop-contrast: ; --tw-backdrop-grayscale: ; --tw-backdrop-hue-rotate: ; --tw-backdrop-invert: ; --tw-backdrop-opacity: ; --tw-backdrop-saturate: ; --tw-backdrop-sepia: ; --tw-contain-size: ; --tw-contain-layout: ; --tw-contain-paint: ; --tw-contain-style: ; color: var(--tw-prose-body); max-width: 65ch; --tw-prose-body: oklch(var(--text-color-100)/); --tw-prose-headings: oklch(var(--text-color-100)/); --tw-prose-lead: oklch(var(--text-color-100)/); --tw-prose-links: oklch(var(--text-color-100)/); --tw-prose-bold: oklch(var(--text-color-100)/); --tw-prose-counters: oklch(var(--text-color-200)/); --tw-prose-bullets: oklch(var(--text-color-200)/); --tw-prose-hr: oklch(var(--border-color-100)/); --tw-prose-quotes: oklch(var(--text-color-100)/); --tw-prose-quote-borders: oklch(var(--border-color-100)/); --tw-prose-captions: oklch(var(--text-color-200)/); --tw-prose-kbd: #111827; --tw-prose-kbd-shadows: 17 24 39; --tw-prose-code: oklch(var(--text-color-100)/); --tw-prose-pre-code: oklch(var(--text-color-100)/); --tw-prose-pre-bg: oklch(var(--background-color-200)/); --tw-prose-th-borders: oklch(var(--border-color-100)/); --tw-prose-td-borders: oklch(var(--border-color-100)/); --tw-prose-invert-body: oklch(var(--dark-text-color-100)/); --tw-prose-invert-headings: oklch(var(--dark-text-color-100)/); --tw-prose-invert-lead: oklch(var(--dark-text-color-100)/); --tw-prose-invert-links: oklch(var(--dark-text-color-100)/); --tw-prose-invert-bold: oklch(var(--dark-text-color-100)/); --tw-prose-invert-counters: oklch(var(--dark-text-color-200)/); --tw-prose-invert-bullets: oklch(var(--dark-text-color-200)/); --tw-prose-invert-hr: oklch(var(--dark-border-color-100)/); --tw-prose-invert-quotes: oklch(var(--dark-text-color-100)/); --tw-prose-invert-quote-borders: oklch(var(--dark-border-color-100)/); --tw-prose-invert-captions: oklch(var(--dark-text-color-100)/); --tw-prose-invert-kbd: #fff; --tw-prose-invert-kbd-shadows: 255 255 255; --tw-prose-invert-code: oklch(var(--dark-text-color-100)/); --tw-prose-invert-pre-code: oklch(var(--dark-text-color-100)/); --tw-prose-invert-pre-bg: oklch(var(--dark-background-color-200)/); --tw-prose-invert-th-borders: oklch(var(--dark-border-color-100)/); --tw-prose-invert-td-borders: oklch(var(--dark-border-color-100)/); font-size: 1rem; line-height: 1.5; display: inline; min-width: 0px; text-wrap: pretty; overflow-wrap: break-word; word-break: break-word;">Tignis' AI technology significantly improves the yield of semiconductor production through several key mechanisms:- Autonomous Root Cause Identification: PAICe Monitor uses AI and machine learning techniques to autonomously identify root causes of critical yield issues, allowing for faster problem resolution 1.

- Multivariate Analysis: The technology identifies complex multivariate and non-linear relationships between process variables and critical wafer measurements, enabling more precise control of the manufacturing process 1.

- Real-time Monitoring: Tignis' AI enables instant deployment of analysis to real-time monitoring, preventing future yield issues by detecting and addressing problems as they arise 1.

- Process Optimization: The AI-driven solutions help tune tools to ensure every wafer is processed with optimal control, leading to improved yield in high-volume production 3.

- Predictive Maintenance: By predicting and preventing potential equipment issues before they occur, Tignis' AI helps maintain consistent production and reduces yield-impacting downtime 2.

- Adaptive Control: The AI continuously learns and improves, allowing for real-time adjustments to compensate for simulation model errors, environmental changes, product changes, or equipment drift, all of which can impact yield 7.

- Virtual Metrology: Built-in virtual metrology enables downstream process modification for better yield, enhancing overall production quality 7.

- Faster Simulations: Tignis' surrogate machine learning models are more accurate and up to one million times faster than physics-based simulations, allowing for rapid process improvements that directly impact yield 5.

By addressing these critical aspects of semiconductor manufacturing, Tignis' AI technology enables manufacturers to significantly improve their production yield, reduce costs, and accelerate time-to-market for new semiconductor products. |