| | Recycling

Moss Landing BESS: Historic battery recycling effort begins for 100,000 damaged lithium-ion batteries

Truckloads of damaged battery cells have already been arriving for rapid processing to recycle spent materials into as much as $30 million of battery grade metal feedstocks.

By

Tristan Rayner

Nov 14, 2025

Recycling

The Moss Landing power plant in 2007. CC BY-SA 3.0 via Wikipedia, photo taken by David Monniaux.

The cleanup at Moss Landing is continuing, with American Battery Technology (ABTC), an integrated critical battery materials company, being contracted by the US Environmental Protection Agency (EPA) to handle, process, and recycle the damaged lithium-ion (Li-ion) battery modules from the 300 MW battery energy storage system (BESS) site.

The 300 MW Phase I energy storage facility at Moss Landing saw a catastrophic fire on January 16, resulting in rapid policy responses from authorities both in the local area and wider across the US. Even globally, stakeholders have placed further emphasis on how to minimize thermal runaway events in containerized battery systems, with companies detailing their fire testing results.

Now, approximately 100,000 battery modules are involved in the largest lithium-ion battery cleanup operation in EPA history. ABTC said in spring 2025, the company underwent an audit and review process and before receiving formal approval from the EPA for the Nevada-based battery recycling facility to receive waste material under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). It has begun receiving “large” shipments of the cells.

It also marks ABTC as one of the few approved battery recyclers in North America able to safely handle batteries that have been damaged and classified as CERCLA waste, including those involved in fire.

The cleanup started in September, with the EPA started overseeing the removal of Li-ion batteries at the Moss Landing facility, a potentially expensive process for all involved. ESS News recently spoke with insurer TMGX, with head of renewables Oliver Litterick noting that when thermal runaway and fires do happen at a site, “ the cost involved in removing … and disposing of it safely are sometimes very, very prohibitive.”

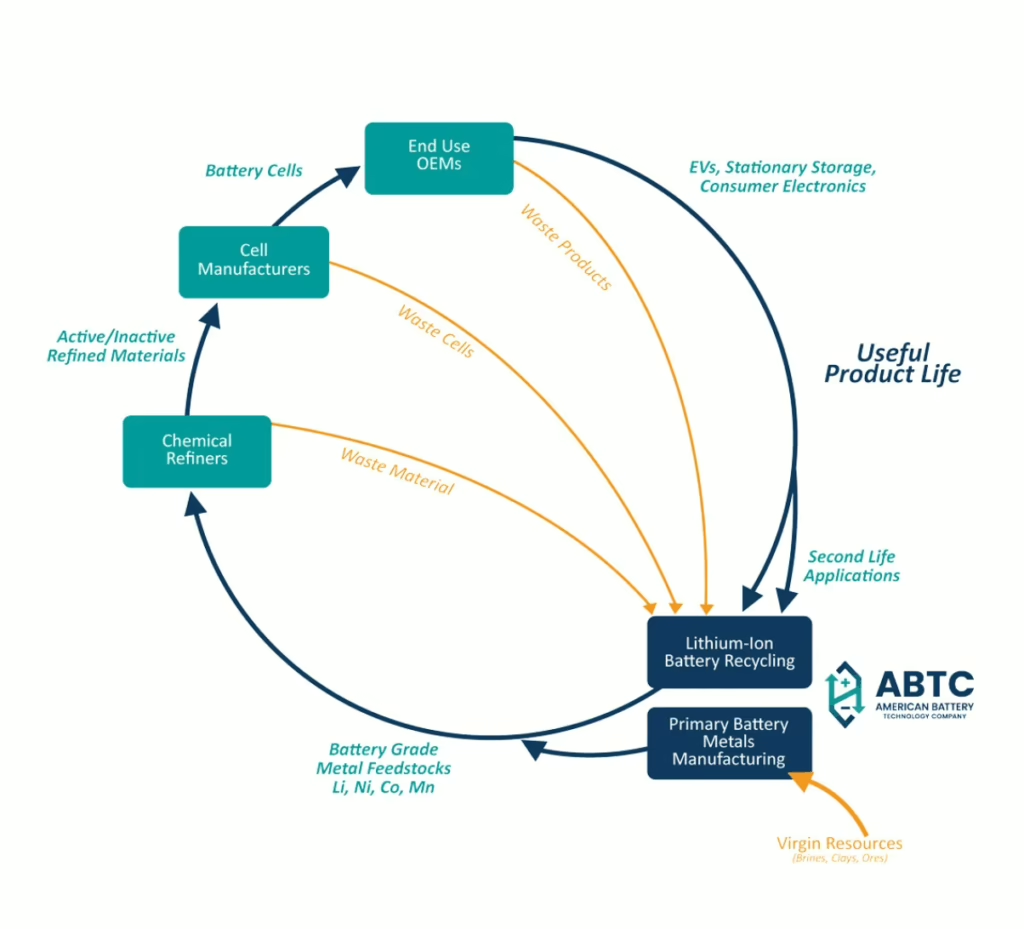

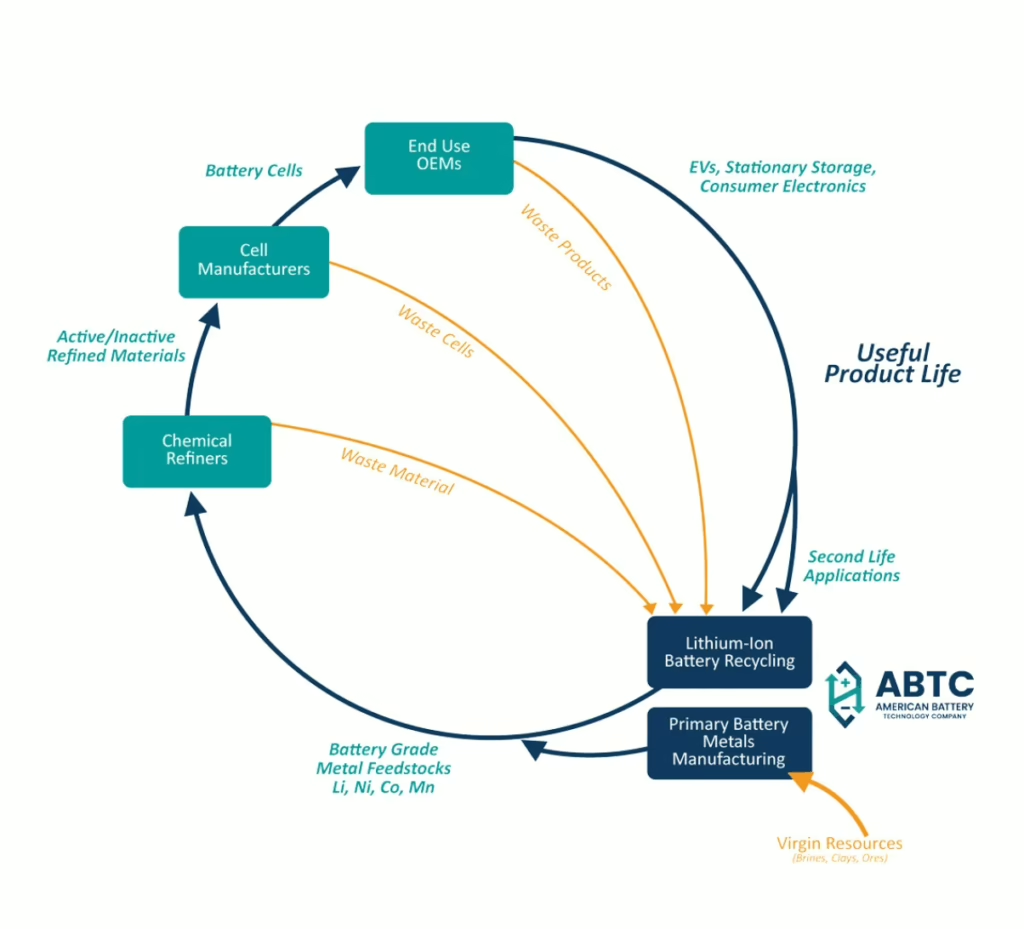

ABTC published the following chart showing the standard recycling process, without providing further details on how damaged cells are handled differently from end-of-life and other cells to be recycled, other than writing “severely damaged modules [require] immediate processing,” while estimating “the total value of recycled materials could approach $30 million if the full volume is processed.”

Image: ABTC

Ryan Melsert, CEO of ABTC, said: “This unprecedented cleanup effort highlights the critical importance of building and deploying advanced domestic critical mineral recycling infrastructure capable of addressing the growing challenges of managing damaged lithium-ion batteries in a safe and responsible manner. We are proud that we have established ABTC as one of the only recyclers in the Western US to be capable of receiving CERCLA materials, and that we have already been processing truckloads of CERCLA material from this project for the past several weeks.”

ess-news.com |

|