Ivanhoe Mines Reports 71,266 Tonnes of Copper Produced by Kamoa-Kakula in Q3 2025; Recovery Efforts Advancing Well

Stage Two dewatering advancing on schedule; approximately 20% complete

Start-up of Africa's largest copper smelter to commence in early November

Kipushi produced a record 57,200 tonnes of zinc in Q3 2025, a quarterly increase of 37%

First platinum-palladium-nickel-gold-rhodium-copper production from Platreef Phase 1 expected in Q4 2025; Phase 2 development underway

Ivanhoe Mines to issue Q2 2025 financial results after market close on October 29; host conference call for investors on October 30

October 07, 2025 6:30 AM EDT | Source: Ivanhoe Mines Ltd.

Johannesburg, South Africa--(Newsfile Corp. - October 7, 2025) - Ivanhoe Mines' (TSX: IVN) (OTCQX: IVPAF) Executive Co-Chair Robert Friedland and President and Chief Executive Officer Marna Cloete announced today the company's third-quarter production results and an update on operational and project activities.

During the third quarter, Kamoa-Kakula's Phase 1, 2, and 3 concentrators milled a total 3.46 million tonnes of ore, producing 71,226 tonnes of copper. Copper production year to date totaled 316,393 tonnes. Production guidance of 370,000 tonnes to 420,000 tonnes of copper in concentrate is maintained, with mining of higher-grade areas on the western side of the Kakula Mine expected from mid-November.

Stage Two dewatering activities are over 20% complete, with underground water levels on the eastern side of the Kakula Mine having declined by over 20 metres since the beginning of September. Stage Two dewatering is expected to be completed by the end of November.

Smelter start-up is scheduled to commence in early November, as the installation of a 60 MW uninterruptible power supply (UPS) unit nears completion. The UPS will safeguard the smelter complex from potential power interruptions during the ramp-up period.

Production rates from Kipushi notably improved during the quarter following the completion of the debottlenecking program in August. In the third quarter, the Kipushi concentrator milled a record 168,862 tonnes of ore at an average milled grade of 37.8%, producing a record 57,200 tonnes of zinc in concentrate. The record quarterly production represented a 37% increase compared to Q2 2025.

Phase 1 operations at the Platreef Mine are expected to commence shortly, with the first feed of ore into the concentrator expected in the coming weeks. Project development work on the Phase 2 expansion is already underway, with the appointment of the engineering, procurement and construction management (EPCM) contractor in the fourth quarter. First production from the Phase 2 concentrator is targeted for Q4 2027.

Founder and Co-Chairman Robert Friedland commented:

"Our recovery efforts at the Kakula Mine are advancing well due to exceptional execution from our operating teams under a decisive plan of action put in place by our management team and joint-venture employees. We are on track to restore Kamoa-Kakula towards its previous copper production levels as we rehabilitate the existing workings and develop new high-grade areas across this Tier-One ore body. Insights gathered during the dewatering efforts will be combined with input from our world-class team of independent experts to design an updated mine plan that will chart Kamoa-Kakula's bright future as a leading producer in the copper industry.

"This quarter should mark a turning point in operations, as we anticipate higher grades from Kakula's western side from next month, with selective mining of the existing workings on the eastern side of Kakula planned from Q1 2026. We're also on the cusp of starting operations at Africa's largest and greenest, direct-to-blister copper smelter, which is expected to drive lower cash costs as we complete its ramp-up.

"In addition, we're extremely excited for imminent first production at the Platreef Mine, which is on schedule for later this month. Given rising prices and interest in platinum-group metals, we are bringing the world's next great precious metals complex online at an exceptionally opportune moment. Platreef's major endowment of nickel, copper, and gold makes it one of the lowest-cost and scalable producers of platinum, palladium, nickel, gold, rhodium and copper on our planet ... and we are already at work on a Phase 2 expansion that will propel Platreef into a Top 10 producer globally."

In preparation for the heat-up of Kamoa-Kakula's state-of-the-art, 500,000-tonne-per-annum, direct-to-blister copper smelter, an operator oversees a training exercise on the slag cleaning furnace blister ladles.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

Summary of quarterly production data from Kamoa-Kakula

| Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | Q3 2025 | | Phase 1 & 2 |

|

|

|

|

| | Ore tonnes milled (000's tonnes) | 2,215 | 2,329 | 2,211 | 1,991* | 1,838 | | Feed grade of ore processed (% copper) | 4.86% | 5.08% | 5.01% | 4.12%* | 2.50% | | Copper recovery (%) | 86.6% | 87.0% | 88.3% | 85.4%* | 81.3% | | Copper in concentrate produced (tonnes) | 94,214 | 102,042 | 97,575 | 71,401* | 37,744 |

|

|

|

|

|

| | Phase 3 |

|

|

|

|

| | Ore tonnes milled (000's tonnes) | 1,050 | 1,326 | 1,512 | 1,631 | 1,618 | | Feed grade of ore processed (% copper) | 2.64% | 2.82% | 2.76% | 2.92% | 2.44% | | Copper recovery (%) | 79.9% | 85.1% | 85.1% | 85.5% | 84.2% | | Copper in concentrate produced (tonnes) | 22,099 | 31,777 | 35,545 | 40,608 | 33,522 |

|

|

|

|

|

| | Combined Phase 1, 2, and 3 |

|

|

|

|

| | Ore tonnes milled (000's tonnes) | 3,266 | 3,655 | 3,723 | 3,622 | 3,456 | | Feed grade of ore processed (% copper) | 4.14% | 4.26% | 4.10% | 3.58% | 2.47% | | Copper recovery (%) | 85.3% | 86.6% | 87.4% | 85.4% | 82.7% | | Copper in concentrate produced (tonnes) | 116,313 | 133,819 | 133,120 | 112,009 | 71,266 |

Data in red denotes a quarterly record

*Phase 1 & 2 production was impacted in the second quarter by seismic activity at the Kakula Mine as announced on May 20, 2025.

Kakula head grades to improve in Q4 2025 as dewatering activities open up higher-grade mining areas

During the third quarter, the Phase 1, 2, and 3 concentrators milled 3.46 million tonnes of ore, producing 71,226 tonnes of copper. Total copper production year to date is 316,393 tonnes.

As announced on June 11, 2025, mining operations on the western side of the Kakula Mine restarted on June 7, 2025. Since mid-June, the mining rate has increased to an average rate of 350,000 tonnes per month (4.2 million tonnes on an annualized basis). To assist with the increase in the mining rates from the western side of the Kakula Mine, the cut-off grade has been lowered to 1.5% copper (previously 2.0%).

Mining on the western side of the Kakula Mine has been focused on higher-elevation areas in the north and southwest, where copper grades are lower than those of the higher-grade centre, which is currently submerged. From mid-November, mining crews plan to advance towards the centre of the western side of the Kakula Mine, improving head grades to between 3.5% and 4.5%.

The Phase 1 and 2 concentrators will continue to process ore from the western side of the Kakula Mine, as well as surface stockpiles, until Q1 2026, when the stockpiles are depleted. Thereafter, selective mining will commence within the existing workings on the eastern side of the Kakula Mine, which will augment rising production from higher-grade areas on Kakula's western side to underpin improved underground mining rates.

The Phase 3 concentrator milled 1.62 million tonnes of ore in the third quarter, producing 33,522 tonnes of copper. For a second consecutive quarter, the Phase 3 concentrator averaged a milling rate equivalent to 6.5 million tonnes annualized, which is 30% higher than design capacity of 5.0 million tonnes per annum. The average quarterly feed grade for the Phase 3 concentrator was 2.44% copper. The cut-off grade was also lowered to 1.5% copper at the Kamoa Mine to achieve higher mining rates, providing sufficient feed for the Phase 3 concentrator and supplementary feed for the Phase 1 and 2 concentrators. For the foreseeable future, it is expected that the feed grade into the Phase 3 concentrator will continue to average approximately 2.5% copper.

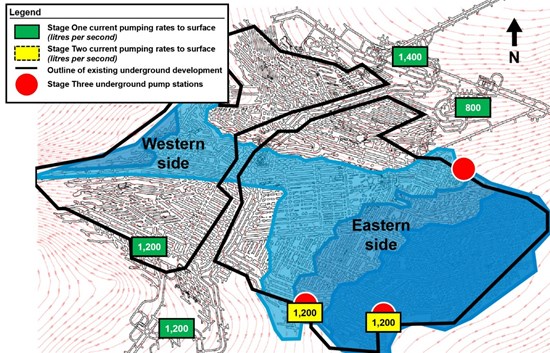

Stage Two dewatering of the Kakula Mine is advancing to plan at over 20% complete

The four Stage Two high-capacity submersible pumps were commissioned over the course of two weeks between the end of August and mid-September. The four pumps are operating at the total design rate of approximately 2,600 litres per second. Including the mobile Stage One pump stations located underground, the total pumping rate at the Kakula Mine, has the potential to pump up to 6,400 litres per second, or 550 megalitres per day, subject to available underground access.

Stage Two dewatering of the Kakula Mine is over 20% complete and is expected to be completed by the end of November 2025, at which point the underground water level is anticipated to be near the bottom of the Stage Two dewatering shafts.

To date, approximately 13 kilometres of lateral development has been rehabilitated. As the water level declines, the mining crews are primarily focused on rehabilitating the access drives required for repositioning the Stage One underground pumping infrastructure, as well as the access towards the Stage Three pump stations, which are currently submerged.

Stage Three pumping will complete the remaining dewatering below the water level accessible by the Stage Two high-capacity submersible pumps, as shown in Figure 1. The mining crews expect to start gaining access to the existing Stage Three pumping infrastructure from November. Each pump station will be refitted and recommissioned with new pump motors and associated electrical infrastructure. Stage Three pumping is expected to be complete in Q1 2026.

Aerial view looking south over the two adjacent sites where the four Stage Two high-capacity, submersible pumps were installed, in pairs, at the bottom of two existing 400-metre deep shafts.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

Figure 1. A schematic of the projected decrease in underground water levels at the Kakula Mine from the end of September (light blue) to the end of November 2025 (dark blue). Dewatering of the entire Kakula mine is expected to be completed in February 2026.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

Water pumped out from the Kakula Mine is fed into nearby settling ponds. Stage Two dewatering of the Kakula Mine is expected to be complete at the end of November 2025.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

The two sites where the Stage Two dewatering infrastructure is located. Both sites were established, with all pumping infrastructure installed and commissioned within just 6 weeks.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

Mine planning and scheduling is well advanced to support the ramp-up of underground mining activities from both the Kakula and Kamoa mines, with a medium-term target of returning the milling rate to 17 million tonnes per year, and ultimately targeting annualized copper production of over 550,000 tonnes

Copper production guidance for 2026 and 2027 will be released once sufficient physical inspection of the newly dewatered areas of the Kakula Mine has been completed. The new life-of-mine plan is expected to be released in Q1 2026.

Smelter start-up scheduled for early November; installation nearing completion of 60-megawatt, battery-powered, uninterruptible power supply facility

Heat-up of Kamoa-Kakula's on-site, direct-to-blister copper smelter is expected to commence in early November 2025. Kamoa-Kakula's management team expects to prioritize the processing of all concentrates produced by the Phase 1, 2, and 3 concentrators through the on-site smelter, with any excess concentrate continuing to be toll-treated at the nearby Lualaba Copper Smelter (LCS), in Kolwezi.

The smelter start-up will commence as the installation of the uninterruptible power supply (UPS) facility nears completion later this month. The 60 MW UPS is designed to provide up to 2 hours of instantaneous back-up power to the smelter, protecting the operation from voltage fluctuations in the DRC grid. In addition to the UPS, there is a further 60 MW of dedicated diesel-powered, back-up generator capacity.

There is sufficient on-site copper concentrate inventory for the smelter start-up in early November. As of September 30, 2025, Kamoa-Kakula's unsold copper in concentrate inventory totaled 59,000 tonnes, which includes 7,300 tonnes located at LCS. The first feed of concentrate into the smelter is expected approximately four to six weeks after heat-up commences.

Members of the smelter team are inspecting the sulphuric acid plant ahead of the furnace heat-up. The smelter is expected to produce up to 700,000 tonnes per annum of high-strength sulphuric acid, which is in high demand across the Central African Copperbelt.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

Kipushi concentrator produced record 52,700 tonnes of zinc in Q3 2025, following completion of the debottlenecking program, which was delivered under budget and ahead of schedule

Summary of quarterly production data from Kipushi

| Q3 2024 | Q4 2024 | Q1 2025 | Q2 2025 | Q3 2025 | | Kipushi Concentrator |

|

|

|

|

| | Ore tonnes milled (tonnes) | 108,065 | 119,619 | 151,403 | 153,342 | 168,862 | | Feed grade of ore processed (% zinc) | 32.12 | 31.72 | 32.16 | 33.37 | 37.81 | | Zinc recovery (%) | 75.78 | 85.07 | 87.93 | 85.22 | 89.36 | | Zinc in concentrate produced (tonnes) | 18,946 | 32,490 | 42,736 | 41,788 | 52,700 |

Data in red denotes a quarterly record

Zinc production from the Kipushi concentrator notably improved during the second half of the third quarter, with multiple records achieved. The improvement in production rates was attributed to the completion of the debottlenecking program, as well as upgrades to the dense media separation (DMS) upstream of the concentrator. Both workstreams were completed in August.

Engineering work on the debottlenecking program commenced in September 2024 to boost the concentrator throughput rate by 20% from 800,000 to 960,000 tonnes of ore per annum. The debottlenecking program was completed in early August, both ahead of schedule and under budget. A seven-day planned shutdown of the concentrator to commission the newly installed debottlenecking equipment and upgrades to the DMS circuit was completed in mid-August.

Multiple concentrator records have since been achieved in the latter half of the third quarter. A record 6,064 tonnes of zinc in concentrate were produced over 7 days in late August, equivalent to an annual production rate of over 315,000 tonnes of zinc, after accounting for availability. Sustaining this production rate would make the Kipushi Mine the world's fourth-largest zinc mining operation.

Despite the improved production rates, operations continue to be impacted by grid instability. An additional six megawatts of back-up generator capacity is in the process of being installed and will be commissioned in the coming weeks. The new generators will increase the total onsite back-up power to 20 megawatts, sufficient to maintain operational continuity during periods of grid instability.

In addition to delivering the debottlenecking program ahead of schedule and under budget, the Kipushi project team has done so with an industry-leading safety record. Throughout construction of the Kipushi concentrator, which started in September 2022 and was completed in June 2024, as well as the recently completed debottlenecking program, the project team at Kipushi did not record a single lost time injury (LTI). This is an outstanding and incredibly rare industry achievement.

Total year-to-date production from the Kipushi concentrator is 137,224 tonnes of zinc in concentrate. Following improved production rates from the recently completed debottlenecking program, Kipushi's 2025 production guidance remains unchanged at between 180,000 and 240,000 tonnes of zinc.

Temwani Nyirenda, Kingki Mining Technician, is conducting scheduled maintenance on an Epiroc Scooptram at the underground workshop in Kipushi.

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

First production from Platreef Mine's Phase 1 concentrator is expected in the coming weeks

The Ivanplats project team is almost operationally ready for the first feed of ore into the Platreef Mine's Phase 1 concentrator, which was completed on schedule in June 2024, and has been kept under a regular care and maintenance program. The first feed of platinum-palladium-nickel-gold-rhodium-copper ore into the Phase 1 concentrator is expected by the end of October.

As announced on May 8, 2025, underground development of the thick, high-grade Flatreef platinum-palladium-nickel-gold-rhodium-copper orebody, on the 850-metre level commenced on April 30, 2025. Since then, a total of 165 metres of reef development in ore has been completed, and of the total 17,125 tonnes of ore blasted, 10,215 tonnes of ore have been hoisted to surface. Reef development on the 750-metre level has also recently commenced. Development ore continues to be hoisted to surface via Shaft #1 and stored in surface stockpiles. The development ore stockpiles will feed the 0.8 Mtpa Phase 1 concentrator during the initial stages of ramp-up.

Equipping of Shaft #3 continues to progress well and is on schedule for completion in Q1 2026. Long hole stoping (production mining) is expected to commence in Q2 2026, once Shaft #3 is commissioned and is ready to hoist.

The underground delineation drilling program, which commenced last year ahead of developing the first long hole ore blocks, has progressed very well with a total of 16,110 meters drilled to date. All assays reconcile well with Ivanplats' geological models and mine plan.

Recruitment continues ahead of the ramp-up of Phase 1, with a total Ivanplats workforce now at over 2,200 employees and contractors, including more than 70% locally-based and 26% female. The workforce will continue to grow as the project team has recently started development work on Phase 2.

Project development on Phase 2 expansion underway, targeting completion in Q4 2027

The Ivanplats project engineering team has already commenced work on the development of Phase 2, with the concentrator expansion targeted for completion in Q4 2027. The EPCM contractor for the 3.3-million-tonne-per-annum Phase 2 concentrator is also expected to be appointed in Q4 2025, with earthworks on the site adjacent to the Phase 1 concentrator scheduled to commence shortly thereafter.

In addition, Shaft #2's concrete headgear is now completed, and the expansion of the shaft to a diameter of 10 metres will commence following the appointment of the contractor in Q1 2026. Raise boring of Shaft #2 to its initial diameter of 3.1 metres was completed in Q4 2024.

Aerial view of the Platreef Mine site, with Shafts #1, #2 and #3 (centre), the run of mine surface stockpiles (top left) and the dry stack tailings facility (top right).

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

The Platreef Mine's 0.8 Mtpa Phase 1 concentrator in the foreground with the mine site central infrastructure and shaft headframes in the background. The 3.3 Mtpa Phase 2 concentrator will be positioned alongside the Phase 1 concentrator

To view an enhanced version of this graphic, please visit:

images.newsfilecorp.com

Ivanhoe Mines to issue Q3 2025 financial results after market close on October 29, and host conference call for investors on October 30, 2025

Ivanhoe Mines will report its Q3 2025 financial results and a detailed update on its operations after market close on Wednesday, October 29, 2025.

The company plans to hold an investor conference call to discuss the second quarter financial results the following day on Thursday, October 30, 2025. Details of the call will be shared closer to the date.

An audio webcast recording of the conference call, together with supporting presentation slides, will be available on Ivanhoe Mines' website at www.ivanhoemines.com.

After issuance, the Financial Statements and Management's Discussion and Analysis will be available at www.ivanhoemines.com and www.sedarplus.ca.

Qualified Persons

Disclosures of a scientific or technical nature at the Kamoa-Kakula Copper Complex, the Platreef Mine and the Kipushi Mine in this news release, have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience, and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is Ivanhoe Mines' Executive Vice President, Projects. Mr. Amos has verified such technical data disclosed in this news release.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Copper Complex, the Platreef Mine, and the Kipushi Mine, each of which is available on the company's website and under the company's SEDAR+ profile at www.sedarplus.ca

- Kamoa-Kakula Integrated Development Plan 2023 Technical Report dated March 6, 2023, prepared by OreWin Pty Ltd., China Nerin Engineering Co. Ltd., DRA Global, Epoch Resources, Golder Associates Africa, Metso Outotec Oyj, Paterson and Cooke, SRK Consulting Ltd., and The MSA Group.

- The Kipushi 2022 Feasibility Study, dated February 14, 2022, prepared by OreWin Pty Ltd., MSA Group (Pty) Ltd., SRK Consulting (South Africa) (Pty) Ltd, and METC Engineering.

- The Platreef Integrated Development Plan 2025, dated February 15, 2025, prepared by OreWin Pty Ltd., Mine Technical Services, SRK Consulting Inc., DRA Projects (Pty) Ltd, and Golder Associates Africa.

The technical reports include relevant information regarding the assumptions, parameters, and methods of the mineral resource estimates on the Kamoa-Kakula Copper Complex, the Kipushi Mine and the Platreef Mine cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal projects in Southern Africa: the expansion of the Kamoa-Kakula Copper Complex in the DRC, the ramp-up of the ultra-high-grade Kipushi zinc-copper-germanium-silver mine, also in the DRC; and the phased development of the tier-one Platreef platinum-palladium-nickel-gold-rhodium-copper mine in South Africa.

Ivanhoe Mines is also exploring its highly prospective, 54-100% owned exploration licences in the Western Forelands, covering an area over five times larger than the adjacent Kamoa-Kakula Copper Complex. Ivanhoe is exploring for new sedimentary copper discoveries, as well as expanding and further defining its high-grade Makoko, Kiala, and Kitoko copper discoveries as the company's next major development projects.

Follow Robert Friedland ( @robert_ivanhoe) and Ivanhoe Mines ( @IvanhoeMines_) on X.

Information contact

Investors

Vancouver: Matthew Keevil +1.604.558.1034

London: Tommy Horton +44 7866 913 207

Media

Tanya Todd +1.604.331.9834

Forward-looking statements

Certain statements in this release constitute "forward-looking statements" or "forward-looking information" within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties, and other factors that may cause the actual results, performance, or achievements of the company, its projects, or industry results, to be materially different from any future results, performance, or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified using words such as "may", "would", "could", "will", "intend", "expect", "believe", "plan", "anticipate", "estimate", "scheduled", "forecast", "predict" and other similar terminology, or state that certain actions, events, or results "may", "could", "would", "might" or "will" be taken, occur or be achieved. These statements reflect the company's current expectations regarding future events, performance, and results and speak only as of the date of this release.

Such statements include, without limitation: (i) statements that start-up of Africa's largest direct-to-blister copper smelter is expected in early November and that the smelter is expected to drive lower cash costs as ramp-up is completed; (ii) statements that Platreef is on track for first feed of ore by end of October and that first platinum-palladium-nickel-gold-rhodium-copper production expected in Q4 2025; (iii) statements that Stage 2 dewatering at Kakula Mine is expected to be completed by the end of November and that dewatering of the entire Kakula mine is expected to be completed in February 2026; (iv) statements that Phase 1 operations at the Platreef Mine are anticipated to commence shortly, with the first feed of ore into the concentrator expected in the coming weeks and that first production from Phase 2 is targeted for Q4 2027; (v) statements that head grades at Kakula are expected to improve to between 3.5% and 4.5% in Q4 2025; (vi) statements that the Phase 1 and 2 concentrators will continue to process ore from the western side of the Kakula Mine, as well as surface stockpiles, until Q1 2026, when the stockpiles are depleted and that thereafter, selective mining will commence within the existing workings on the eastern side of the Kakula Mine, which will augment rising production from higher-grade areas on Kakula's western side to underpin improved underground mining rates; (vii) statements that for the foreseeable future feed grade into the Phase 3 concentrator will continue to average approximately 2.5% copper; (viii) statements that mining crews at Kakula expect to start gaining access to the existing Stage Three pumping infrastructure from November, that each pump station will be refitted and recommissioned with new pump motors and associated electrical infrastructure and that Stage Three pumping is expected to be complete in Q1 2026; (ix) statements that copper production guidance for 2026 and 2027 will be released once sufficient physical inspection of the newly dewatered areas of the Kakula Mine has been completed and that the new life-of-mine plan is expected to be released in Q1 2026; (x) statements that the first feed of concentrate into the smelter is expected approximately four to six weeks after heat-up commences; (xi) statements that the smelter is expected to produce up to 700,000 tonnes per annum of high-strength sulphuric acid, which is in high demand across the Central African Copperbelt; and, (xii) statements that long hole stoping (production mining) at Platreef is expected to commence in Q2 2026, once Shaft #3 is commissioned and is ready to hoist.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results, and will not necessarily be accurate indicators of whether such results will be achieved. Many factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to: (i) uncertainty around the rate of water ingress into underground workings at Kakula; (ii) the ability, and speed with which, additional equipment can be secured for Stage Two of the Kakula dewatering; (iii) the continuation of seismic activity at Kakula; (iv) the state of underground infrastructure at Kakula; (v) uncertainty around when future underground access can be secured at Kakula; (vi) the fact that future mine stability at Kakula cannot be guaranteed; (vii) the fact that future mining methods may differ and impact on Kakula operations; and (viii) the ultimate conclusion of the assessment of the cause of the seismic activity at Kakula and the impact of same on the mining plan at the Kamoa Kakula Copper Complex. Additional factors also include those discussed above and under the "Risk Factors" section in the company's MD&A for the three and six months ended June 30, 2025, and its current annual information form, and elsewhere in this news release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; changes in the rate of water ingress into underground workings; the continuation of seismic activity; the state of underground infrastructure; delays in securing underground access; changes to the mining methods required in the future; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this news release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this news release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this news release.

The company's actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors outlined in the "Risk Factors" section in the company's MD&A for the three and six months ended June 30, 2025, and its current annual information form.

SOURCE: Ivanhoe Mines Ltd. SOURCE: Ivanhoe Mines Ltd. |