re <<tech>>

scmp.com

China unveils power of thorium reactor for world’s largest cargo ship

Technological breakthrough could revolutionise commercial shipping, naval engineering and deep sea operations if rolled out at scale

Stephen Chenin Beijing

Published: 11:00pm, 5 Nov 2025

Updated: 9:01am, 6 Nov 2025

China has unveiled critical details of a revolutionary cargo ship under development: a nuclear-powered vessel that can carry 14,000 standard shipping containers.

But what makes this ship truly groundbreaking is that it will be powered by a thorium-based molten salt reactor (TMSR) with a thermal output of 200 megawatts – matching the power level of the S6W pressurised water reactor used in the US Navy’s most advanced Seawolf-class nuclear attack submarines.

Unlike traditional nuclear reactors that rely on uranium and require massive cooling systems and high-pressure containment, this new Chinese reactor uses thorium, a safer, more abundant and proliferation-resistant nuclear fuel.

And critically, the reactor does not need water for cooling, allowing it to be smaller, quieter and inherently safer than conventional designs.

If successfully deployed at scale, this technology could trigger a paradigm shift in commercial shipping.

While the ship’s concept was first revealed in 2023, few technical details were available.

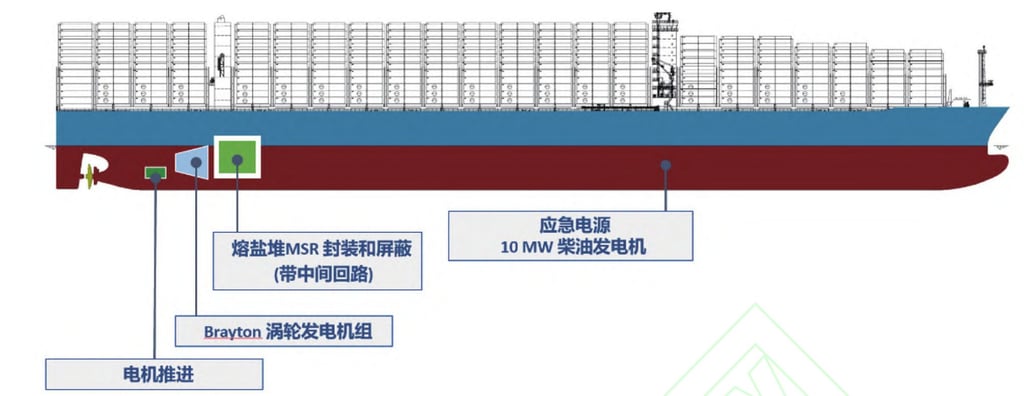

Blueprint of the thorium-powered nuclear cargo ship, which can carry 14,000 containers. From left to right, the labels read “motor propulsion”, “Brayton turbine generator set”, “molten salt pack MSR encapsulation and shielding (with intermediate circuit)” and “emergency power, supplying 10 megawatt diesel generator”. Image: Handout

Writing in Chinese trade publication Ship & Boat on October 15, Hu Keyi, a senior engineer with Jiangnan Shipbuilding Group, disclosed critical specifications and explained China’s strategic choice of the thorium molten salt reactor for maritime use.

The 200MW heat generated by the reactor is not used directly to drive the ship, according to Hu. Instead, it powers a supercritical carbon dioxide (sCO2) generator using the Brayton cycle – a highly efficient thermodynamic process that converts heat into electricity far more effectively than traditional steam turbines.

The Brayton cycle uses compressed gas – in this case, carbon dioxide – heated to extreme temperatures, then expanded through turbines to generate power. Supercritical CO2 behaves like both a liquid and a gas, allowing for compact, high-efficiency systems.

This system will generate 50MW of electrical power – enough to propel the massive vessel across oceans for years without ever stopping for fuel. For emergencies, the ship will also carry a 10MWe backup diesel generator.

One of the biggest fears about nuclear ships is a meltdown or radiation leak. But in the article Hu said the thorium-fuelled solid-core molten salt reactor was inherently safe.

The reactor operates at atmospheric pressure, eliminating the risk of explosive pressure build-up.

The core runs at around 700 degrees Celsius (1,292 degrees Fahrenheit), but thanks to a strong negative temperature coefficient, the reaction naturally slows down as temperature rises – preventing runaway reactions.

There are two passive decay heat removal systems: a natural circulation cooling system inside the reactor compartment and an emergency drain system that can safely evacuate molten salt into shielded, passive cooling tanks if needed.

In a worst-case scenario, if cooling fails, the molten salt fuel would drop into a safety chamber and solidify – trapping radioactive materials and preventing widespread contamination.

In addition, the entire reactor is designed as a sealed, modular unit with a 10-year operational lifespan. After that, instead of refuelling, the whole reactor module is replaced – drastically reducing the risk of leaks or human error.

Thanks to the high-temperature operation and advanced sCO2 power cycle, the thermal-to-electric conversion efficiency reaches 45 to 50 per cent – a massive improvement over the approximately 33 per cent efficiency of conventional nuclear reactors that use steam, according to Hu.

Hu also revealed that China was exploring other nuclear-powered vessel designs: a Suezmax oil tanker powered by a lead-bismuth cooled fast reactor, and a floating nuclear power station using high-temperature gas-cooled reactors.

However, these designs will have lower power outputs compared to the thorium molten salt reactor used in the container ship.

COSCO Shipping’s Pisces is one of the world’s largest container ships, with capacity for 20,000 TEUs. Photo: Xinhua

Thorium is not just safer – it is also far more abundant than uranium. China holds vast thorium reserves, particularly in Inner Mongolia, where a single mine’s tailings contain enough thorium to power the entire country for over 1,000 years at current energy consumption levels.

While the United States built the first thorium reactor in the 1960s at Oak Ridge National Laboratory in Tennessee, the programme was abandoned due to technical challenges, including corrosion of pipes by molten fluoride salts.

China, however, has persisted. In 2025, it achieved a historic milestone: its experimental thorium molten salt reactor in the Gobi Desert became the world’s first to achieve long-term stable operation. A larger, power-generating demonstrator reactor is now under construction.

Despite the promise, huge hurdles remain. “The capital cost of a nuclear-powered merchant ship is expected to be significantly higher than that of a conventional vessel,” Hu wrote.

Key financial and operational barriers include high upfront construction costs, difficulty securing private financing due to perceived risks, limited insurance coverage for nuclear maritime incidents and ongoing expenses for reactor maintenance, spent fuel handling, decommissioning and specialised crew training.

While nuclear fuel itself is cheap and stable in price, Hu notes that economic viability hinges on whether long-term fuel savings can outweigh the massive initial investment and operational complexity.

“Commercial shipping projects may require government support or guarantees,” Hu wrote. “Private companies alone cannot bear such enormous construction and operational risks.” |